Thin Film Processing

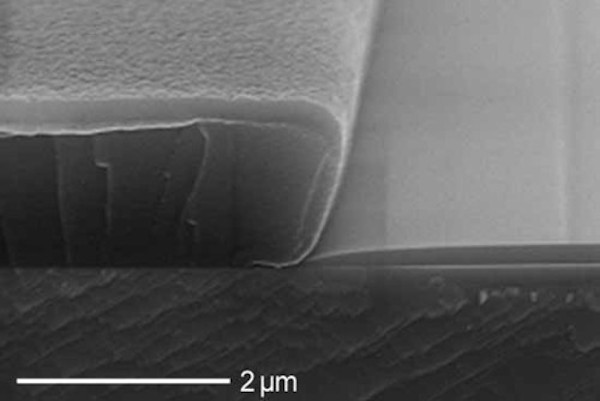

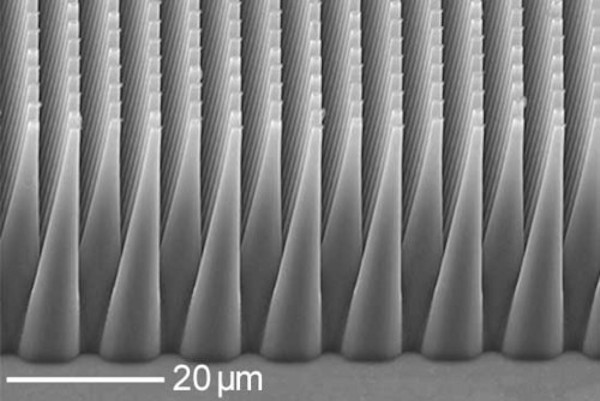

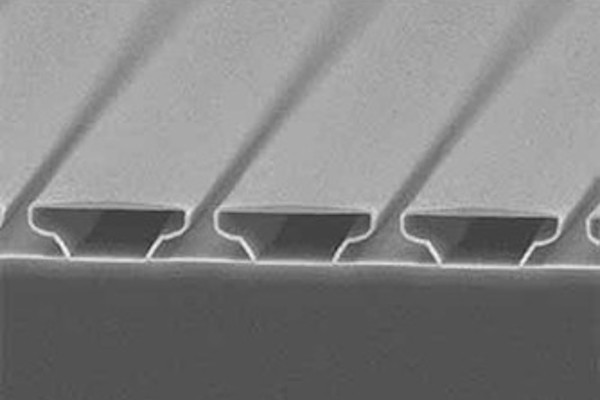

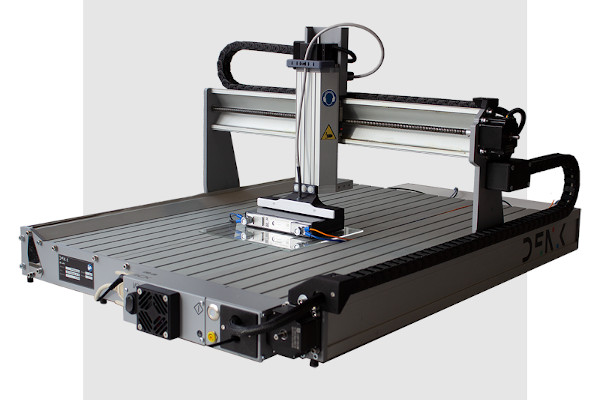

Depositing and etching thin films and coatings

Thin film processing tools from Mi-Net Technology are used to deposit or etch thin films and coatings for a variety of applications.

Featured products

Explore featured products from across our product range

Smartphone based optical tensiometer to measure the surface properties of materials

Fast and easy measurement of thin films with optional mapping

Industries

Our products are used in a range of industries worldwide

The design and fabrication of semiconductor devices within the wider...

Research and quality control in the pharmaceuticals and cosmetics industry...

Contact us

We’d love to hear from you

We’re here and ready to provide information and answers to your questions

Policy Information

©Mi-Net 2023. All Rights Reserved.

Website by Fifteen.co.uk