Tribometers

Robust, modular, and powerful pin on disc tribometers

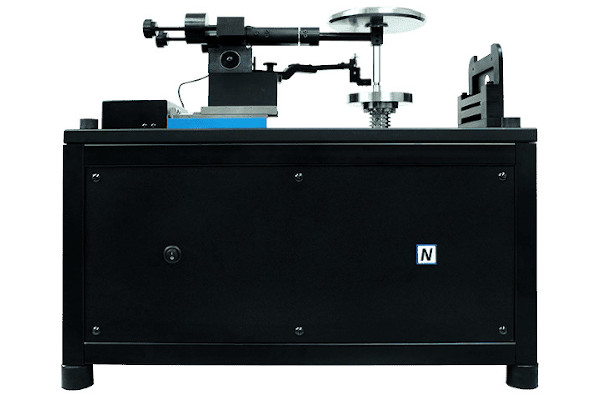

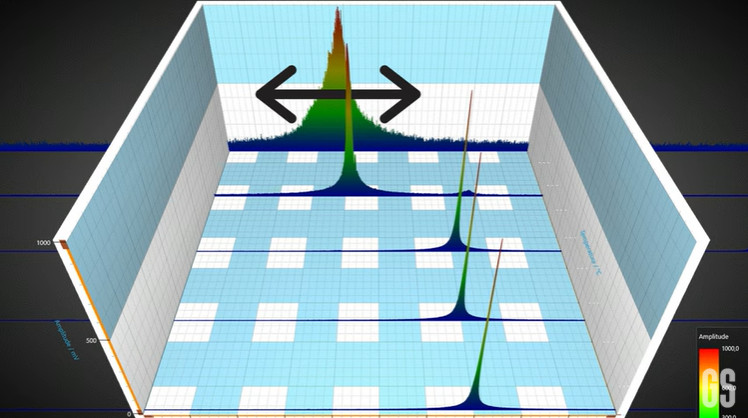

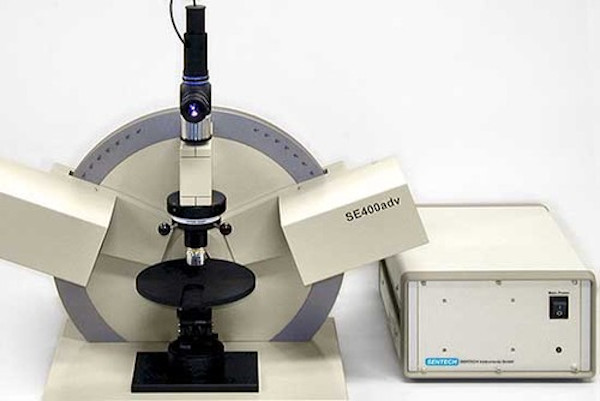

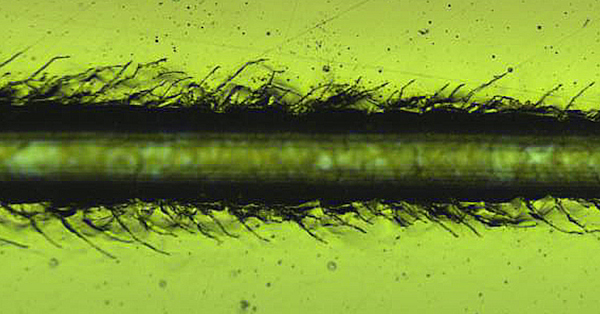

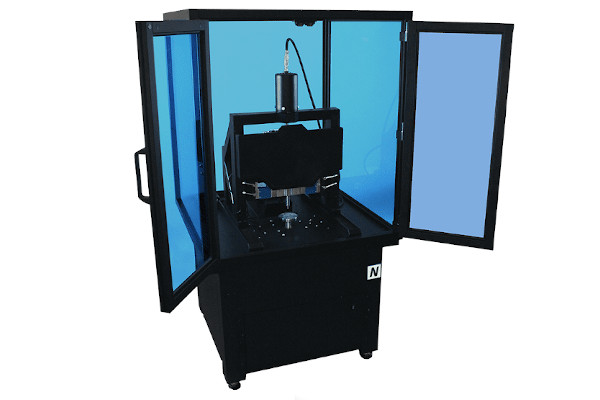

We supply pin on disc tribometers from Nanovea of Irvine California. Nanovea tribometers are built to be simple but powerful and are modular allowing the user to add a range of additional test and environmental options. Nanovea tribometers are installed at both research and industrial customers and come in both compact desktop and fully functional stand alone designs.

You can find out more on the Nanovea website here.

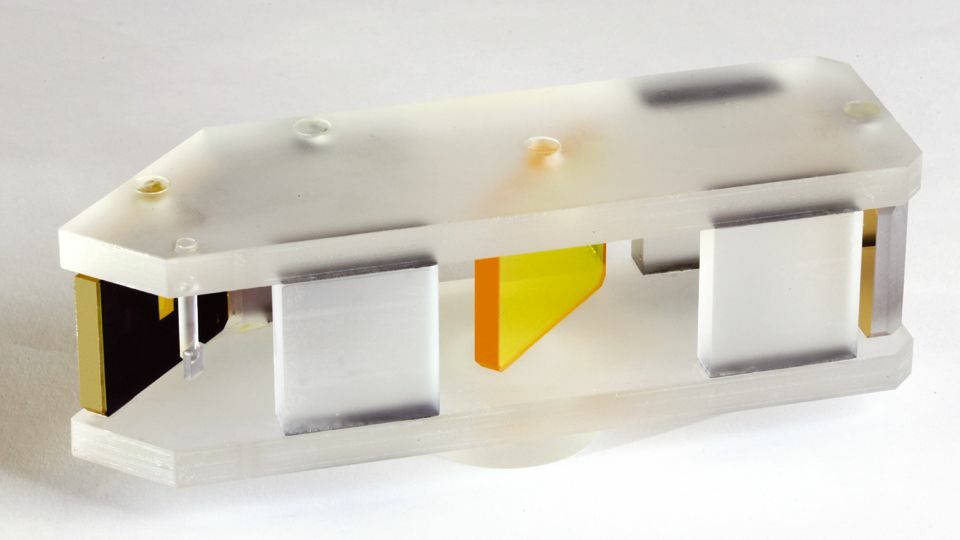

Compact pneumatically loaded pin on disc tribometer up to 100N

Advanced pneumatically loaded pin on disc tribometer up to 2000N

Contact us

We’d love to hear from you

We’re here and ready to provide information and answers to your questions

Policy Information

©Mi-Net 2023. All Rights Reserved.

Website by Fifteen.co.uk