“A gem cannot be polished without friction, nor a man perfected without trials”

Lucius Annaeus Seneca

Friction. There’s just no getting away from it. Your car tires that won’t last forever. The door hinge that starts squeaking after a few years of use. These everyday annoyances all stem from wear and friction. These forces shape the durability and performance of materials in everything from aerospace components to medical implants. Managing these forces is the domain of tribology, the science of friction, lubrication, and wear. And at the heart of tribology lies tribology testing — a field dedicated to ensuring materials can withstand the test of time and use.

A Jost Cause

1966 was not just a big year for English football. It was also the year that British engineer Peter Jost coined the term tribology – a field that had been vastly overlooked despite its industrial and economic importance. His report highlighted the cost of friction, wear, and corrosion to the UK economy. Today, it is estimated that 20% of the total energy expenditure in the world is due to the impact of friction and wear in the transportation, manufacturing, power generation, and residential sectors.

The word tribology derives from the Greek work ‘tribos’ meaning ‘rubbing’. Tribology has been shaping human progress for centuries. Ancient civilisations would use animal fat to lubricate chariot axles and would construct stone ramps with sand and water to reduce friction when moving heavy blocks for the pyramids. Today, tribology is a cornerstone of engineering, ensuring machines last longer, operate efficiently, and withstand the test of time.

It wasn’t until da Vinci’s experiments in the 15th century that frictional laws were first recorded. In the 18th century, French scientist Guillaume Amontons formalised the fundamental principles of friction. Jost’s report would then revolutionise modern tribology, prompting industries to invest heavily in lubrication science and wear-resistant materials.

Without proper attention to tribology, we are simply wearing down our progress

Peter Jost

The Fundamentals of Tribology – and Why Testing Matters

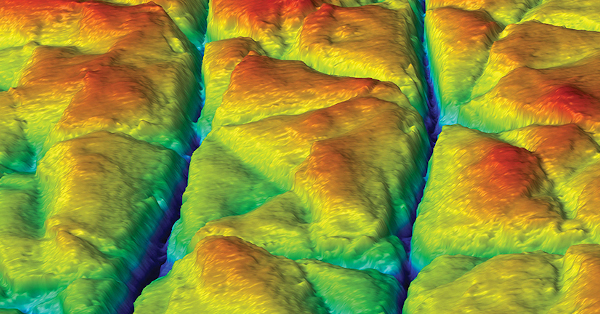

At its core, tribology is the study of interacting surfaces in relative motion. It encompasses:

- Friction – the resistance to motion when two surfaces come into contact.

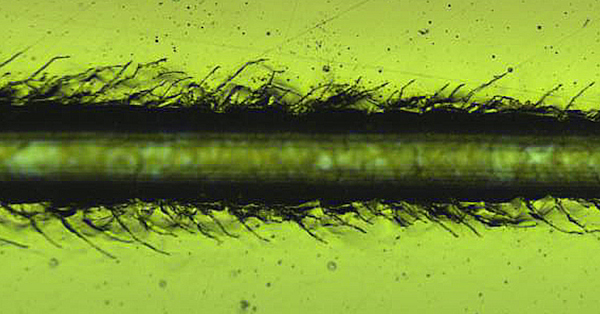

- Wear – the gradual removal of material due to friction and mechanical action.

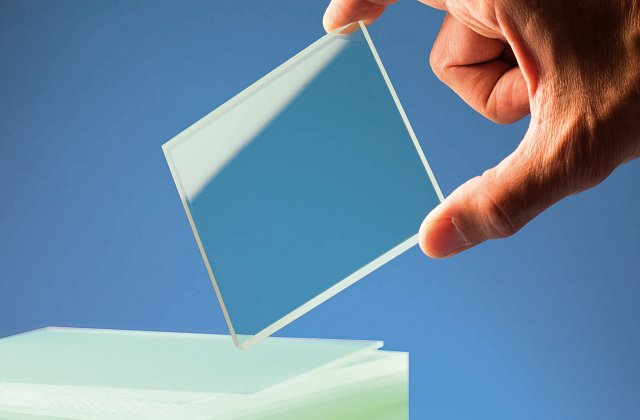

- Lubrication – the application of substances to reduce wear and friction.

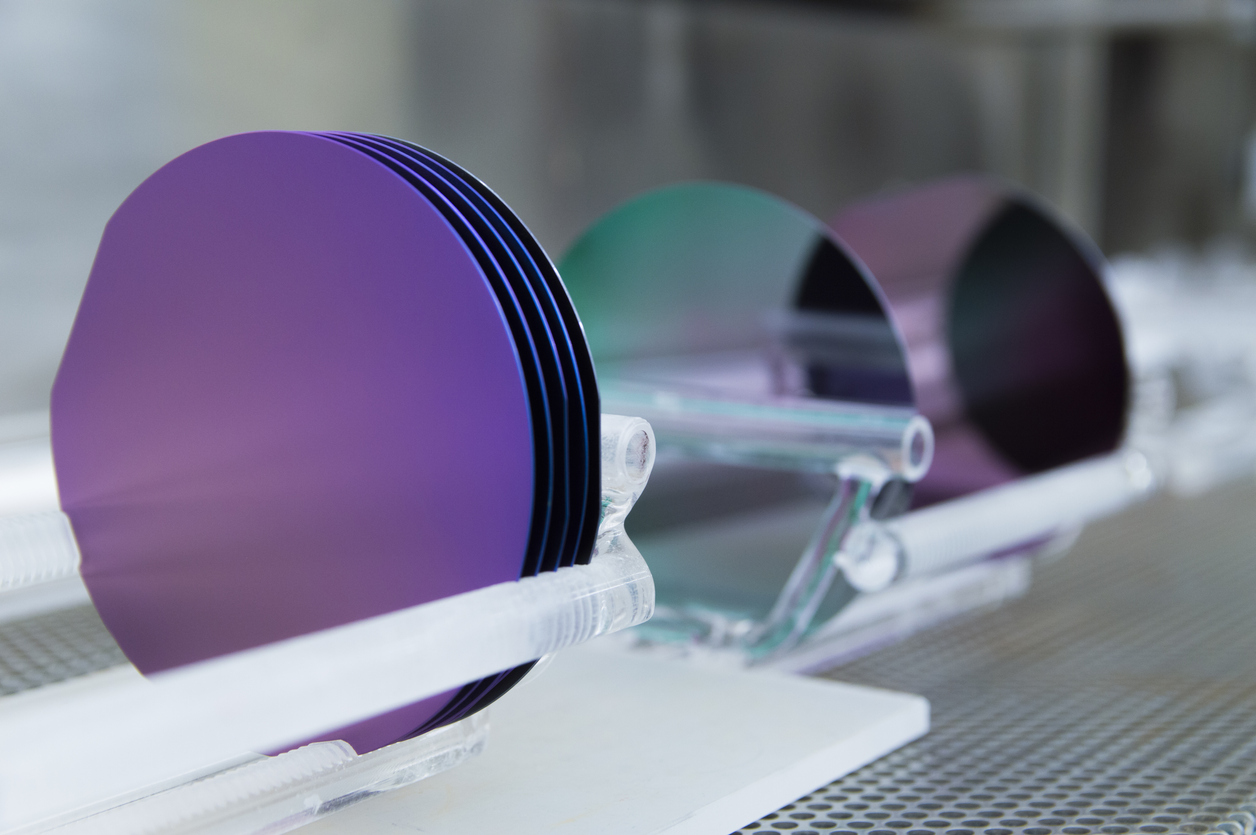

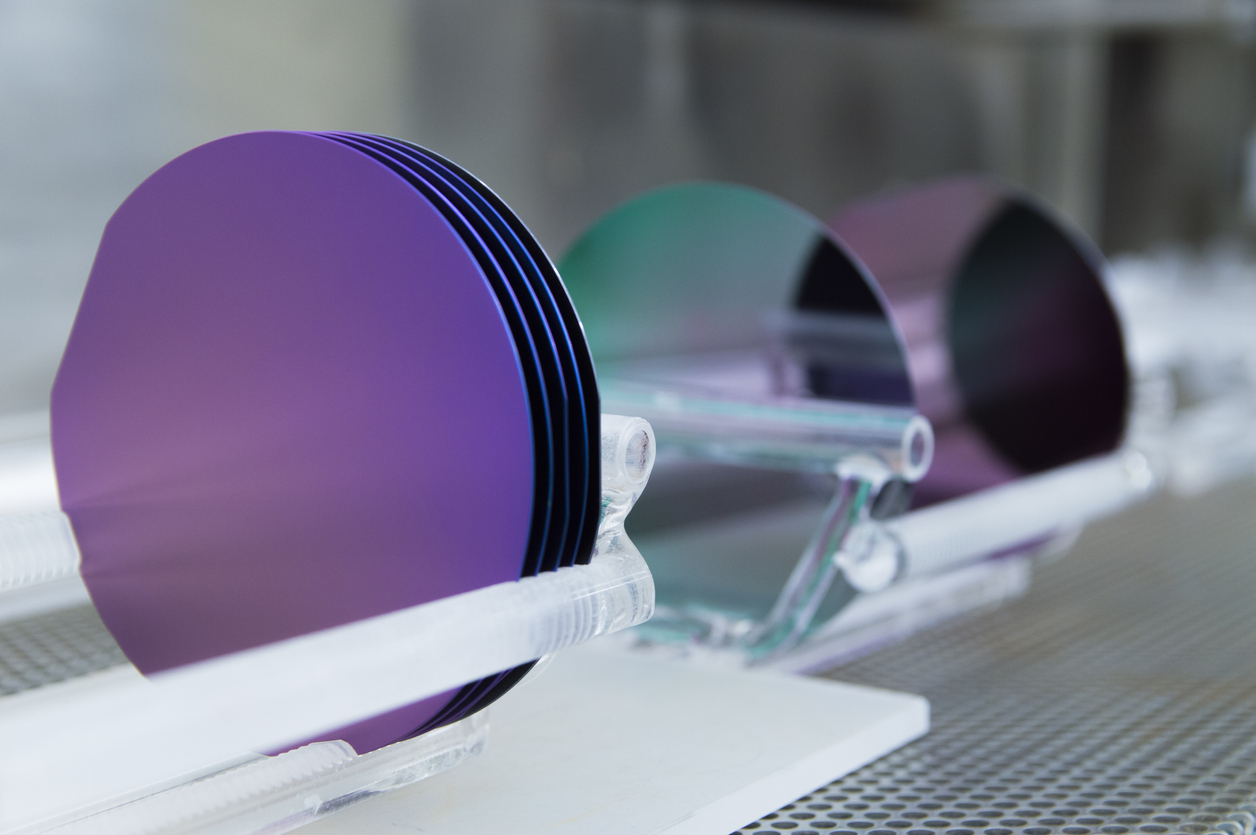

Understanding these factors is crucial in industries ranging from aerospace to medical implants, where even microscopic wear can have major implications. Modern industries rely on high-performance materials, but even the strongest materials degrade over time. Wear resistance is key to enhancing the longevity and efficiency of components. By studying how materials respond to friction and wear, engineers can design better coatings, lubricants, and surface treatments to enhance performance and durability.

How Does it Actually Work?

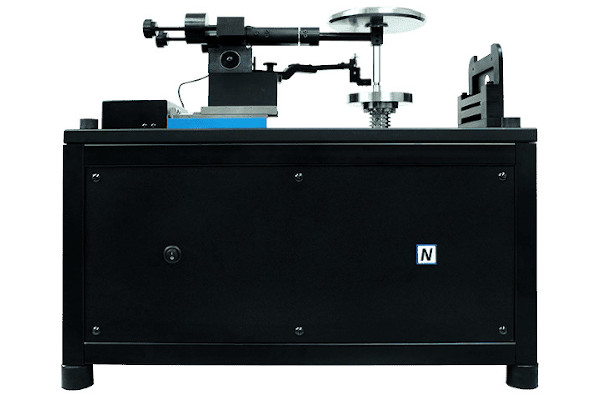

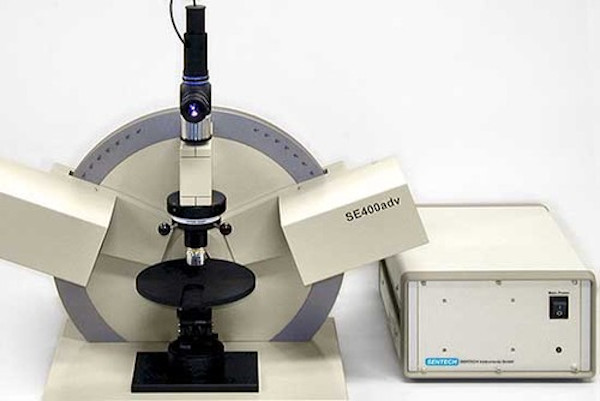

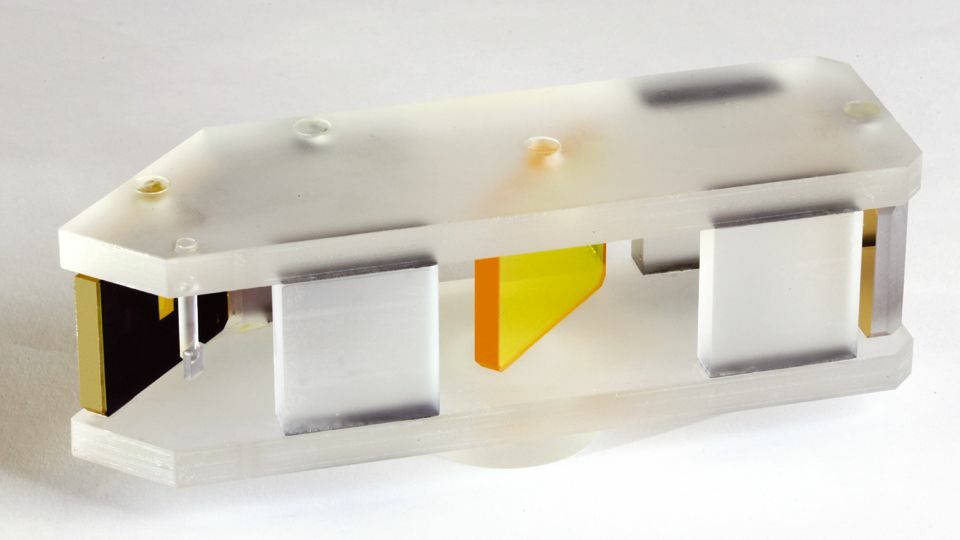

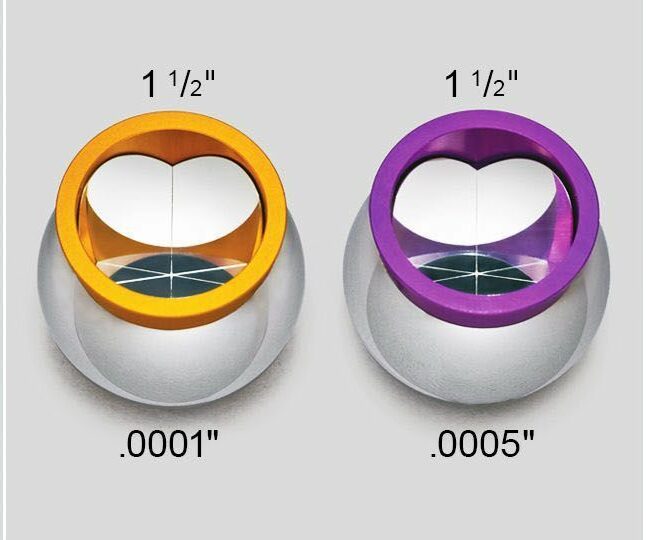

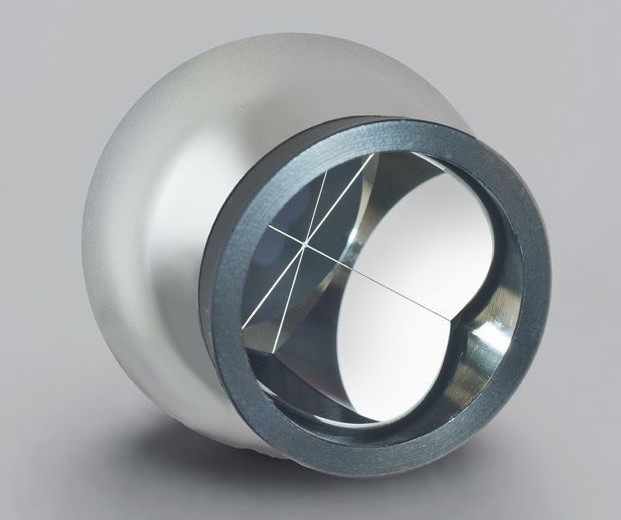

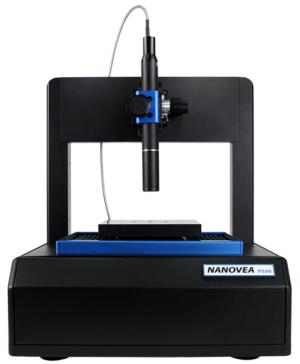

Tribometers are specialized instruments designed to measure friction, wear, and lubrication properties under controlled conditions. They can be tailored for a range of applications:

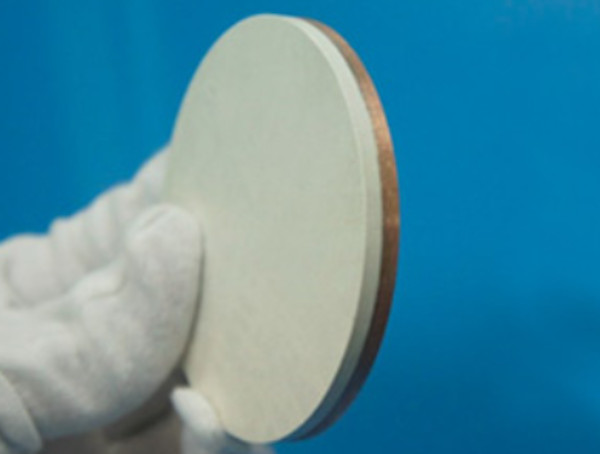

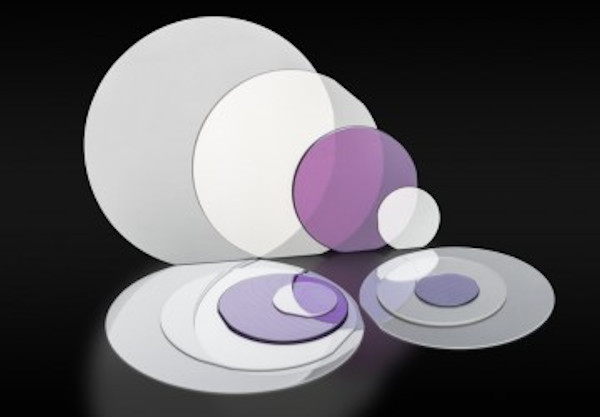

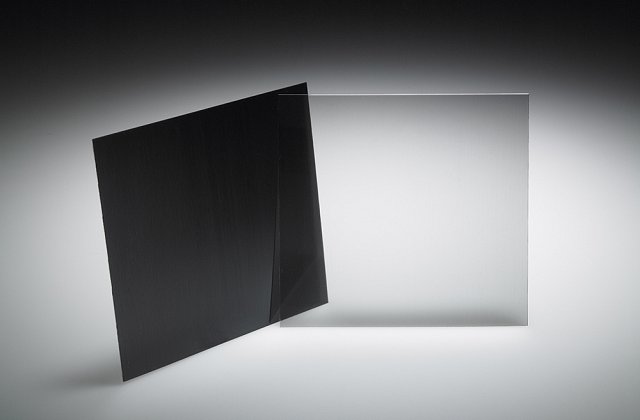

- Pin-on-Disk Tribometers – Simulating contact between materials, these devices measure friction and wear over time.

- Ball-on-Flat Testers – Evaluating surface coatings and treatments to improve durability.

- Reciprocating Tribometers – Assessing wear behaviour under oscillatory motion, mimicking real-world mechanical conditions.

Tribology testing is indispensable in numerous fields:

- Automotive & Aerospace: Reducing engine wear, improving fuel efficiency, and optimizing component durability.

- Medical Devices: Ensuring the longevity of prosthetics and implants.

- Energy Sector: Enhancing the wear resistance of wind turbine components and drilling equipment.

- Manufacturing: Improving tool coatings and material efficiency in industrial machinery.

Keeping Things Moving

Mi-Net provides high-precision tribometers designed to meet the demands of cutting-edge research and industrial applications. Our solutions empower engineers to develop wear-resistant materials, reduce maintenance costs, and improve overall performance.

Effective tribology testing ensures:

- Longer-lasting materials – reducing maintenance and replacement needs.

- Greater energy efficiency – lowering friction means less wasted energy.

- Improved safety and reliability – essential in medical, automotive, and aerospace applications.

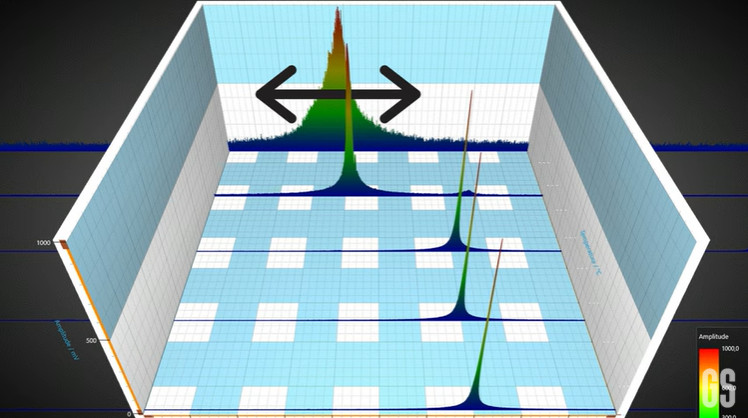

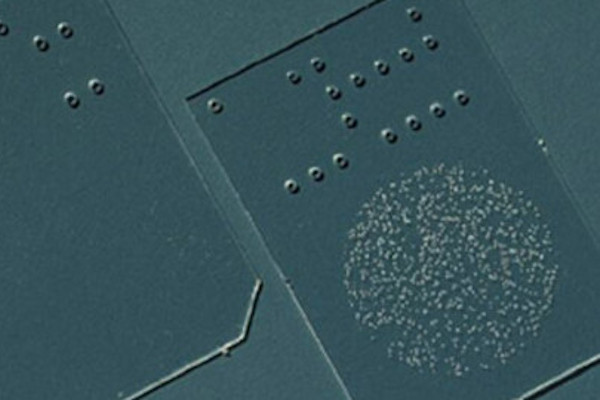

At Mi-Net, we provide state-of-the-art tribometers that evaluate wear and friction under controlled conditions. These instruments measure key parameters such as:

- Coefficient of friction (CoF) – how much force is required to slide two surfaces against each other.

- Wear rate – the material loss over time under specific loads.

- Lubrication effectiveness – determining how well lubricants reduce friction and wear.

Mi-Net offers a range of advanced tribometers that provide precise, reliable tribology testing for research and industry. Whether you need to optimize a material for extreme environments or ensure product longevity, our solutions help you make data-driven decisions for superior wear resistance. Learn more here.