Mechanical Testing

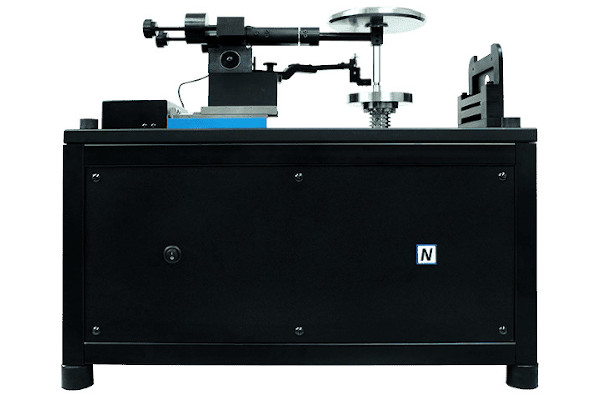

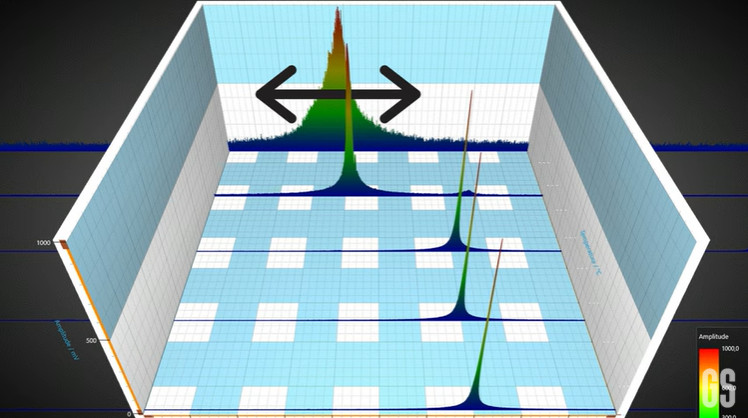

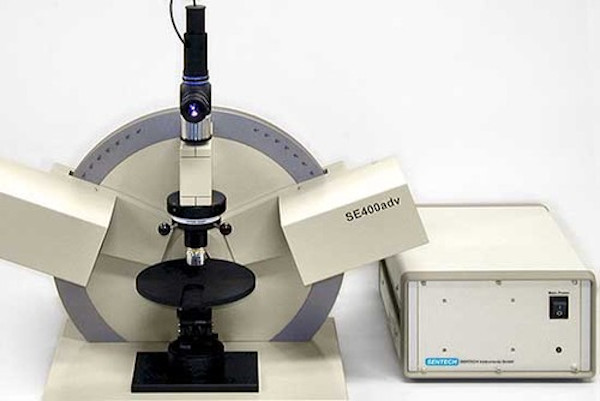

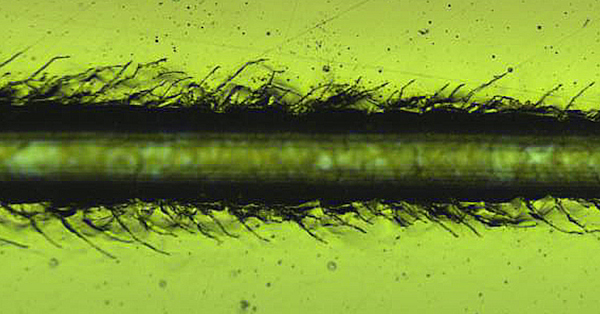

Scratch, indentation and wear testing all on one tool at nano and micro load ranges

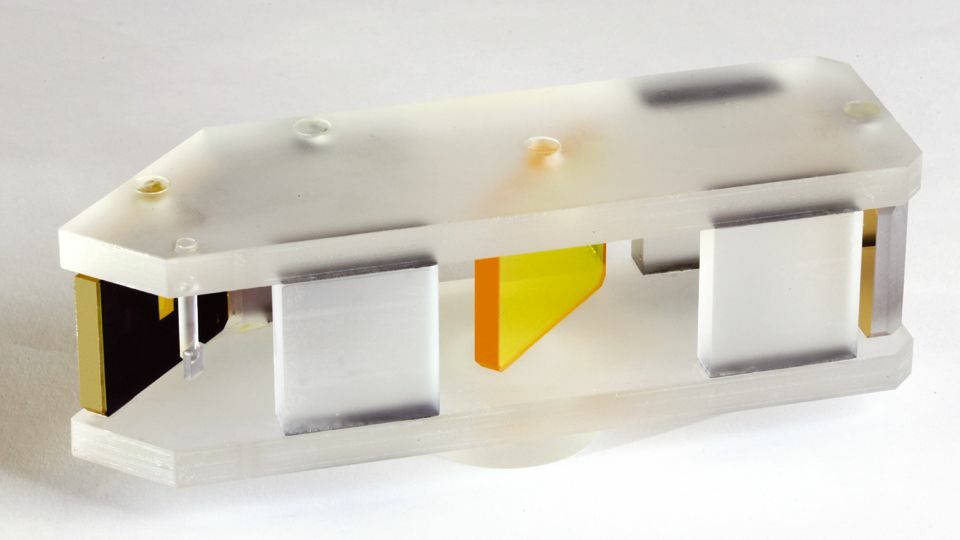

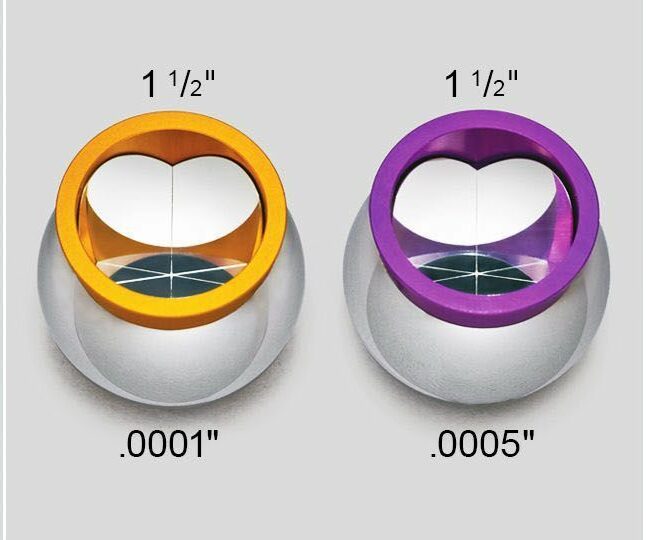

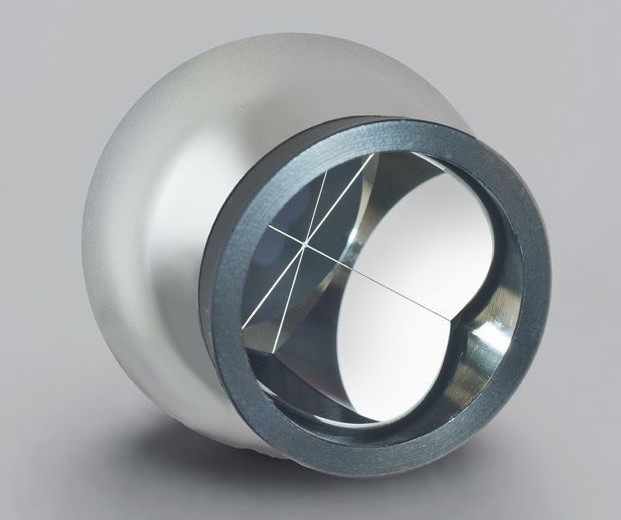

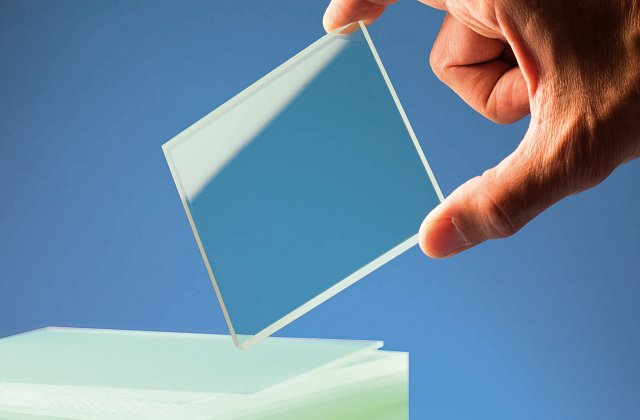

Nanovea Mechanical Testers provide unmatched multi-function Nano and Micro test modules on a single platform. Each module is capable of indentation, scratch and wear testing and has been designed with high quality leading edge technology to ensure data is accurate and repeatable. In addition a full range of environmental modules are available to simulate specific application conditions.

You can find out more on the Nanovea website here.

Scratch, indentation and wear across Nano and Micro load ranges on a flexible upgradeable platform

Scratch, indentation and wear across Nano or Micro load ranges on a compact benchtop platform

Contact us

We’d love to hear from you

We’re here and ready to provide information and answers to your questions

Policy Information

©Mi-Net 2023. All Rights Reserved.

Website by Fifteen.co.uk