A comprehensive range of sputtering materials and sizes available

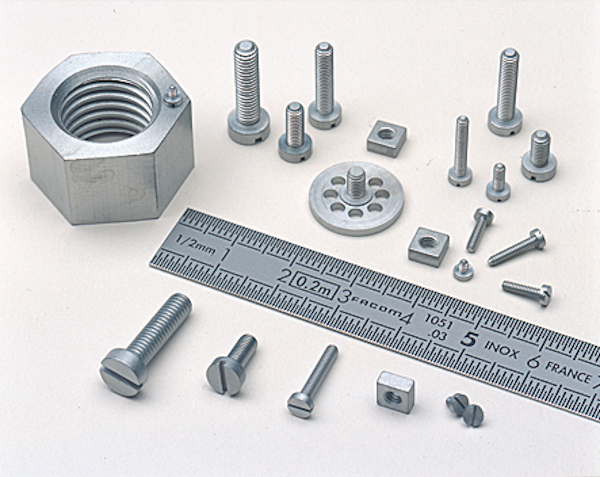

Micro machined components in strategic materials such as molybdenum, tantalum, titanium and niobium

Garnet crystals and substrates for epitaxy

J-GRAPHENE is ahigh quality, low defect graphene dispersion

Indium and gallium antimonide. The InSb detectors are sensitive between 1 µm to 5µm wavelengths.

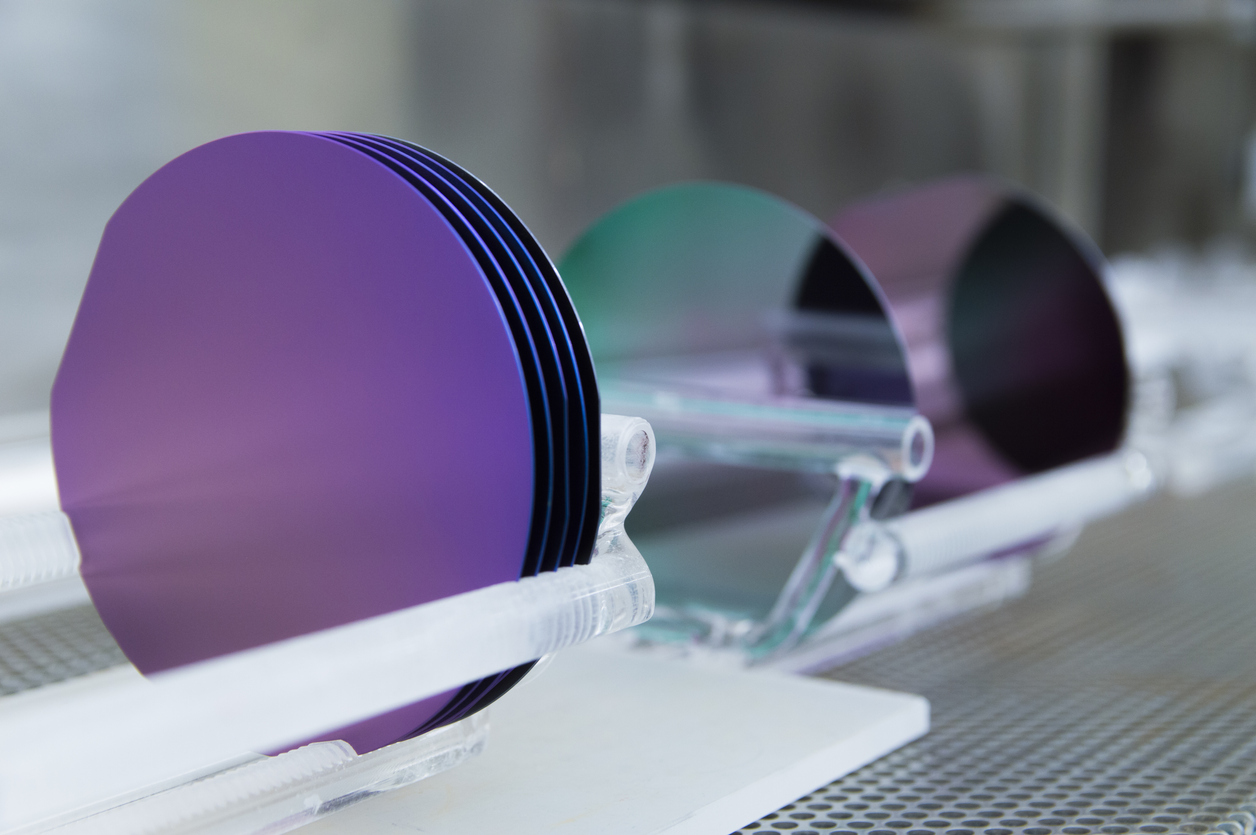

Czochralski (Cz) and float zone (Fz) for a large range of semiconductor applications

Scratch, indentation and wear testing all on one tool at nano and micro load ranges

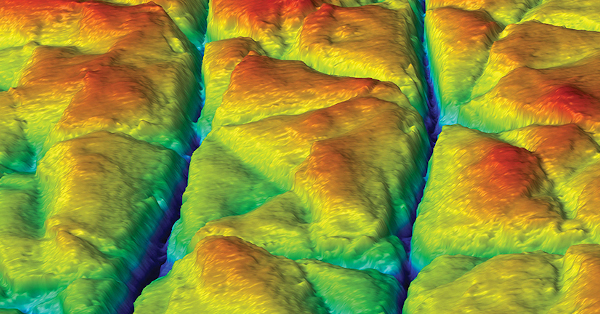

3D non-contact profilometers for collecting and analysing sample height data

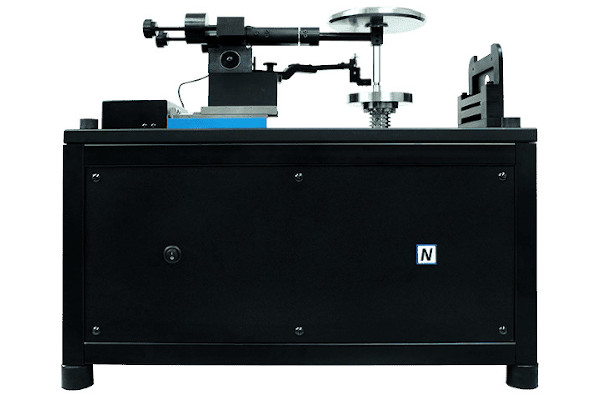

Robust, modular, and powerful pin on disc tribometers

Advanced 3D optical measurement solutions for quality assurance in production

Non-contact technology measuring real time strength and direction of electrical currents

Reproducing the wear interaction between a surface and the human finger

Measurement of surface tension between liquids and solids

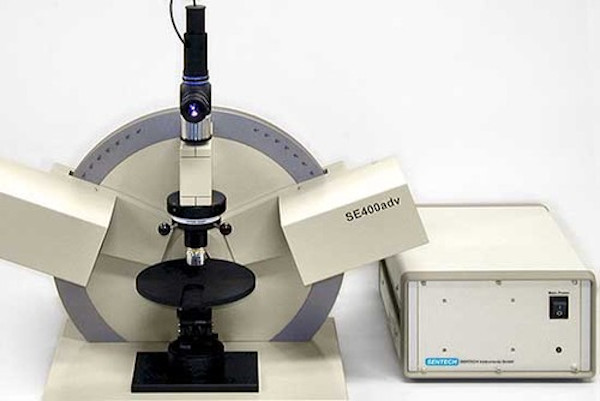

Determining thin film properties by change in polarisation of light

Measuring thin film properties by reflection

Tribology testing in ambient or tailored environments

Real life testing of finished products in respect of resistance to hand abrasion

Scratch & indentation for hardness, elastic modulus, adhesion, cohesion plus more

Gain a deeper understanding of your materials

Measure surface roughness, form, profile, finish plus more

Low damage plasma enhanced chemical vapour deposition

Low damage etching and nano structuring

Deposition of layers in the nanometer scale

Deposition of coatings by the vacuum evaporation technique

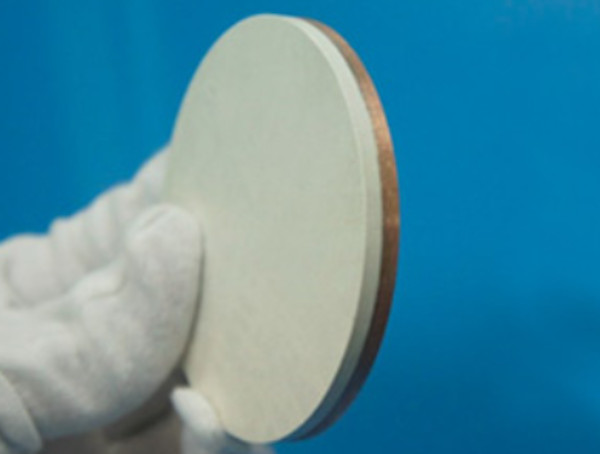

Deposition of coatings by the sputtering technique

The dispersion, mixing, pulverization or emulsification of materials

Scintillator materials grown in crystal form

Scintillator material in organic form

Materials for the measurement of radiation dose

Sapphire in sheet, tube, rod and component form

LiF, Quartz or SiO2, InSb, Si, Ge, PET, ADP, Beryl, TlAP, RbAP, KAP and CsAP

Bespoke leak testing systems for small or large parts

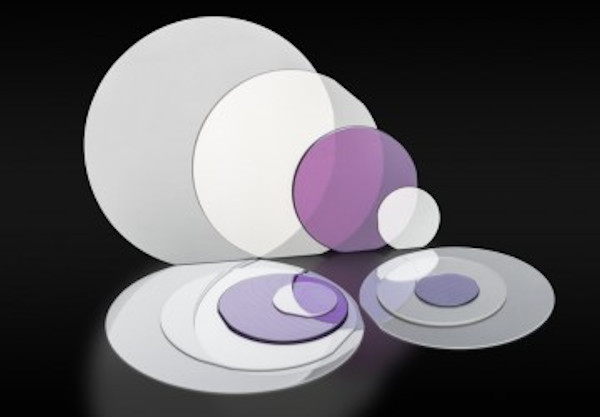

High performance laser optics from Alpine Research Optics

Powerful, easy to use and cost effective AI based image recognition

A comprehensive solution for laboratories using several types of microscope and profilometer

Benchmark technology for 2D and 3D surface texture analysis and metrology, seamlessly integrates with profilometers and other surface measuring equipment

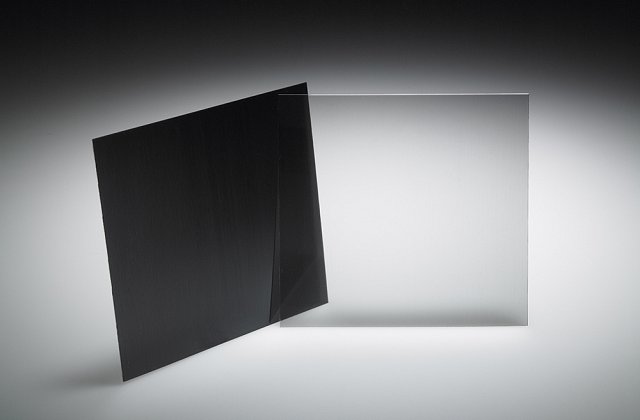

Conductive coating on one side to prevent EMI/RFI

Plastic optical filter with broadband AR coating on both sides

Privacy Glass & Light Control Film

The Droplet Lab Dropometer is a unique smartphone based optical tensiometer used to measure the surface properties of materials. The system has been shown to achieve 0.01% accuracy in contact angle measurement with respect to Young-Laplace and polynomial fitting models and an accuracy of 0.001% for surface tension measurements.

The tensiometer is simple to operate, compact and portable. The Dropometer offers researchers and educators the technical capabilities normally found in far more expensive and bulky equipment.

Designed by experts in tensiometry and backed by peer-reviewed research, the Droplet Lab Dropometer is the only smartphone based tensiometer suitable for both corporate and academic R&D.

“The world of surface science simplified with smartphone technology”.

Droplet Lab was founded in 2016 by Dr Alidad Amirfazli, faculty member at York University, and two of his researchers, Dr Huanchen Chen and Dr Jesus L.Muros-Cobos.

Use the Dropometer to measure Contact Angle, Surface Tension, Surface Energy and Sliding Angle Measurements.

Cost Effective

The Droplet Lab Dropometer drastically reduces the initial investment costs associated with tensiometers while maintaining high end features. The system also offers a flexible subscription based plan so you only pay when you need measurements.

Easy to Use

The app at the heart of Droplet Lab is simple and intuitive to use, bypassing the need for expensive user training. With Droplet Lab you can be up and running in less than 20 minutes.

Easy to Assemble

The assembly of similar competing tensiometer systems can be a complex process that has to be performed on-site and at cost by the manufacturer. Droplet Lab offers a device that can be quickly and easily assembled without specific training.

Smartphone Based

The Dropometer Tensiometer is built to work with smartphone technology and so the system doesn’t require the use of additional laptops or desktop computers. The smartphone also adds to the portability.

Peer Reviewed

The Droplet Lab Dropometer is built on patented technology designed by experts in the field of tensiometry and has undergone extensive peer review, ensuring that the system operates to the highest standards.

Portable

Traditional tensiometers are heavy and unwieldy making their transportation a delicate task. The Dropometer is significantly smaller and lighter making it portable and the ideal choice for teaching and fieldwork measurements.

A list of potential applications for the Dropometer are as follows:

Paper & Packaging

Surface Treatment and Coatings of Paints

Coating of Glass

Coating of Metals

Wetting and Coating of Textiles

Surface Treatment of Wood

Coating of Polymers

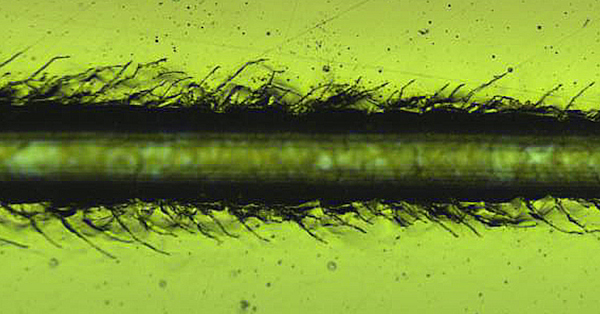

Coating of Fibres

You can read published papers about the Dropometer here – https://dropletlab.com/scientific-validation/.

Resources related to the Droplet Lab Dropometer.

We’re here and ready to provide information and answers to your questions

©Mi-Net 2023. All Rights Reserved.

Website by Fifteen.co.uk