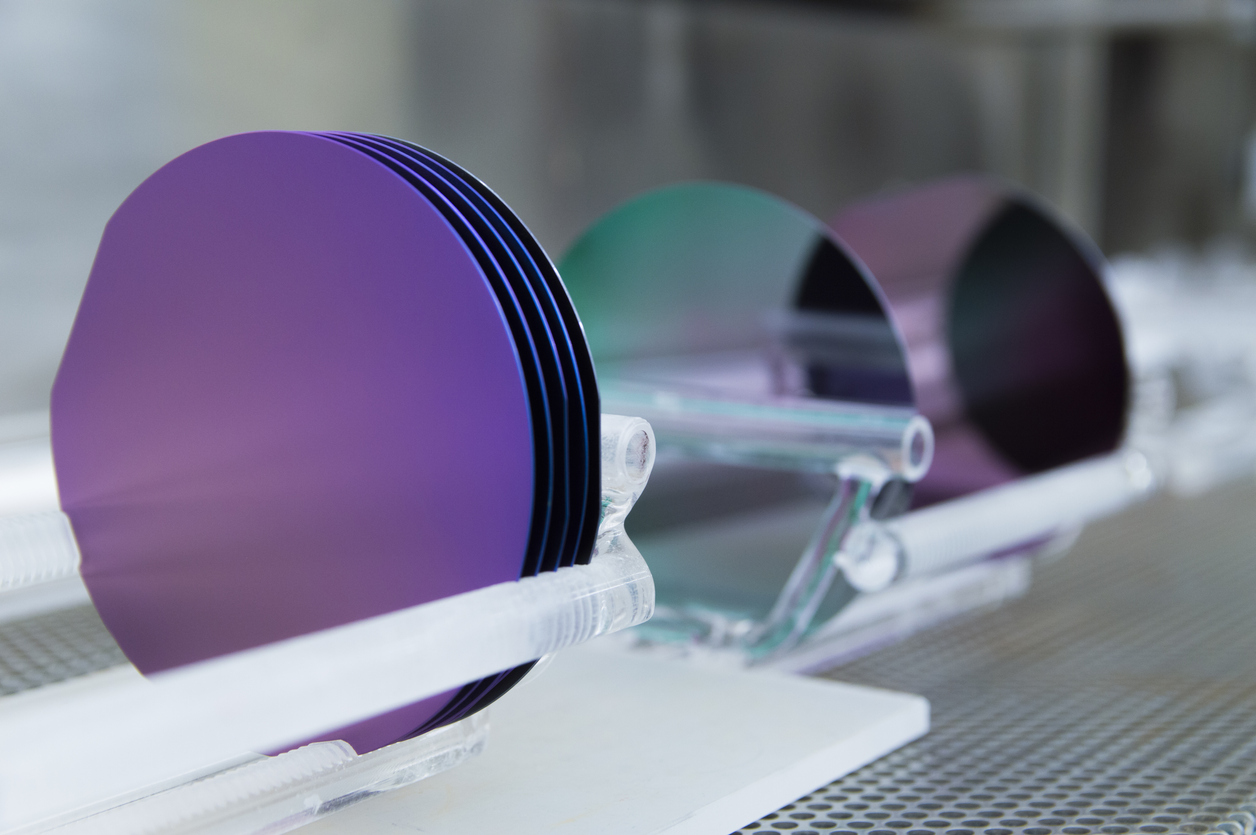

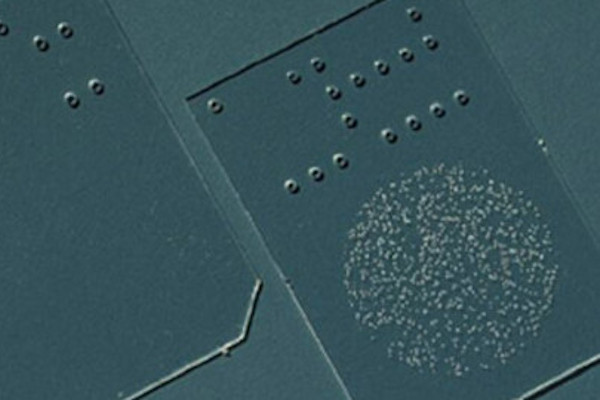

Atomic Layer Etching is a hot topic in research these days with increased activity in 2D materials driving the need for increasingly precise etch rates in the sub-nanometer range.

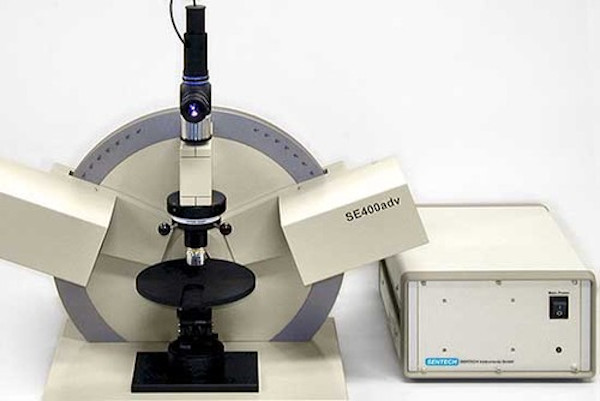

Precise etch rates can only be achieved in tandem with highly precise and reliable metrology tools. Only SENTECH can deliver a fully integrated system with their own Atomic Layer Etch technology coupled with their own thin film metrology solution.

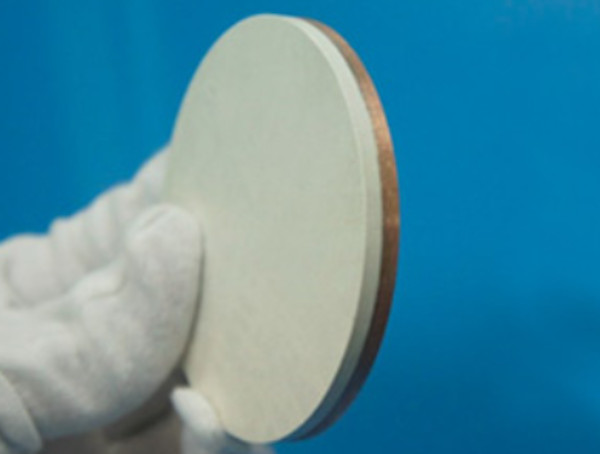

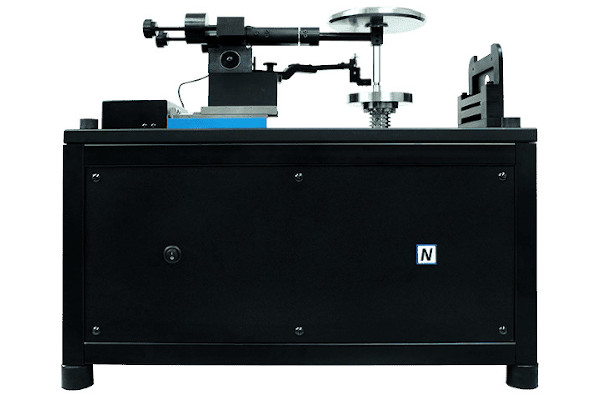

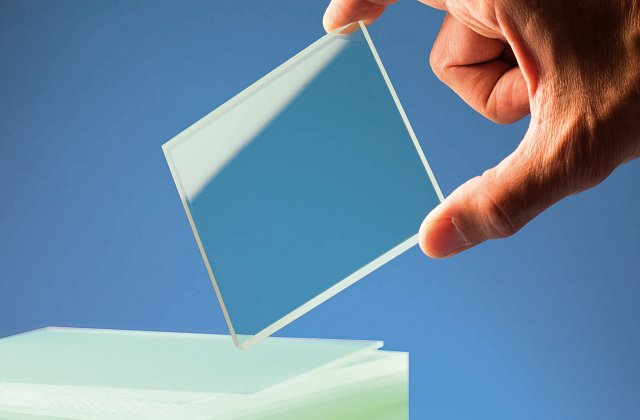

This application note introduces the SENTECH SI500 ALE etching tool equipped with the SENTECH AL Real time Monitor (AL RTM). The AL RTM tool is a laser-based in-situ ellipsometer that allows the determination of film thickness throughout the ALE process. The AL RTM plays a dual role by monitoring a running process and accelerating process optimisation.

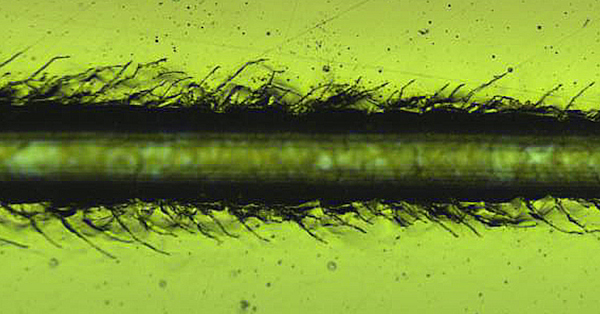

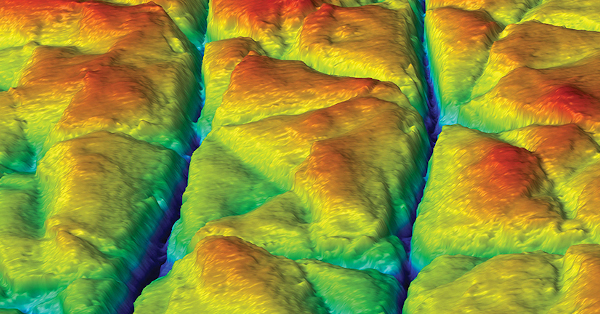

In this application note we present two examples to demonstrate the advantages of in-situ diagnostics for ALE process development. a Cl2-based ALE process for Al2O3 was investigated.

Note Summary – This application note demonstrates the low-damage etching capabilities of the SENTECH SI 500 ICP ALE tool. It is equipped with the proprietary Planar Triple Spiral Antenna (PTSA 200), a unique inductively coupled plasma (ICP) source. We also presented two use cases for the SENTECH AL Real Time Monitor for ALE process development. Both the investigations of the ALE window and the synergy test could be carried out on one single sample, thus demonstrating significant cost and time efficiencies.

To request a pdf copy of the full application note you can click the Request Application Notes link below or you can contact us.