Profilometers

3D non-contact profilometers for collecting and analysing sample height data

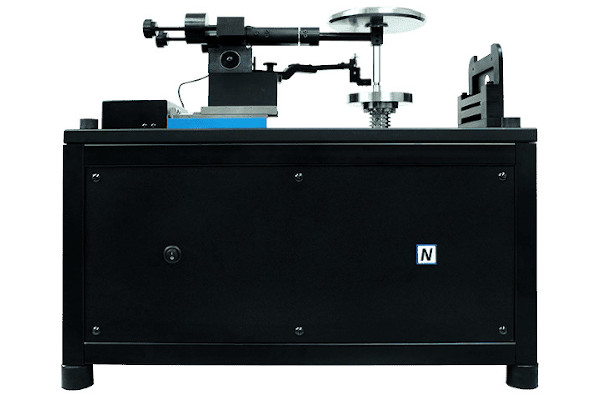

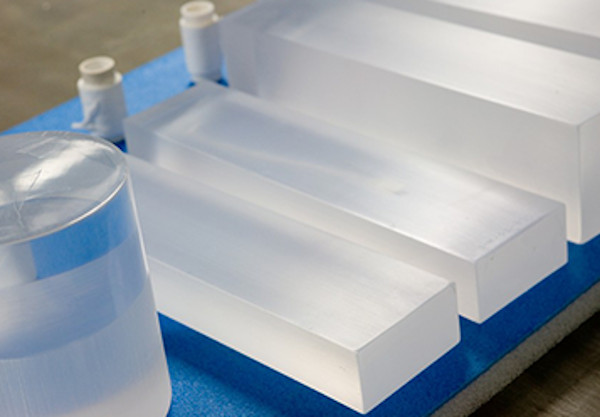

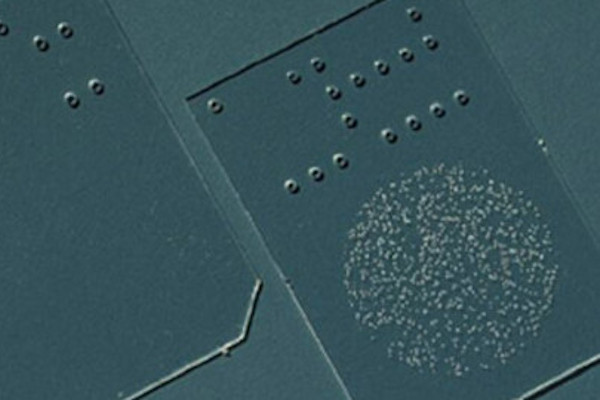

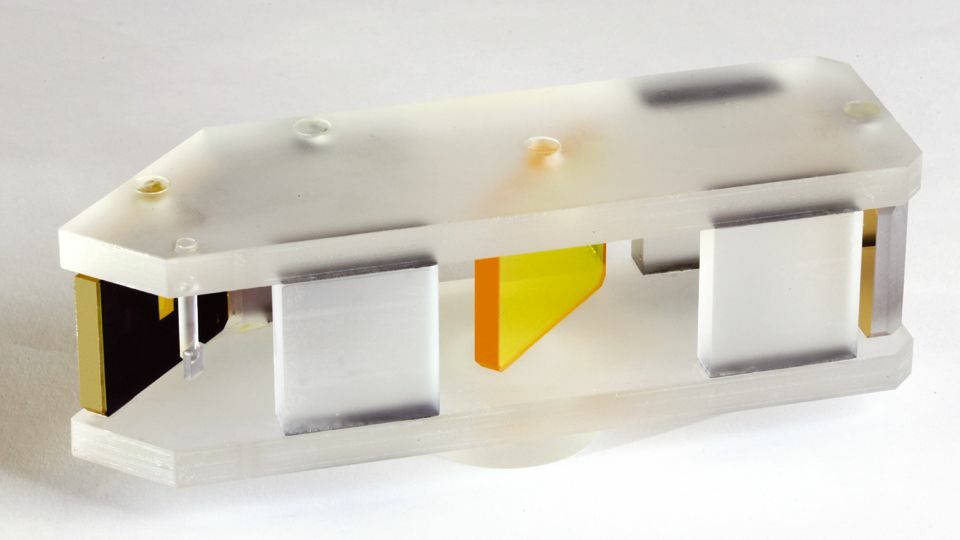

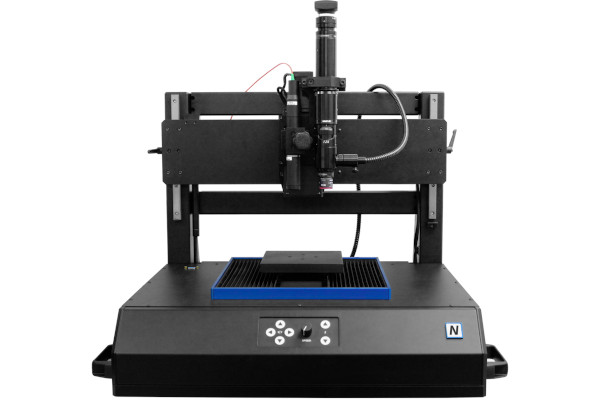

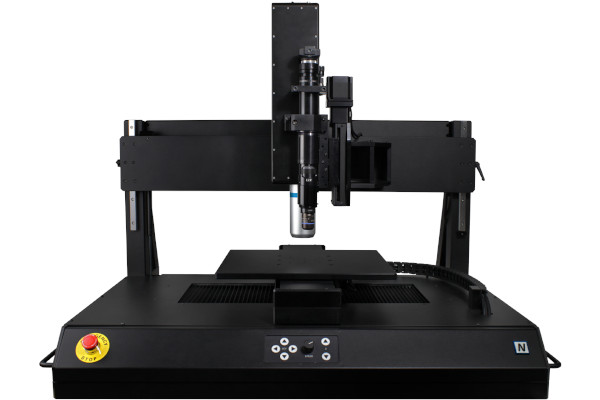

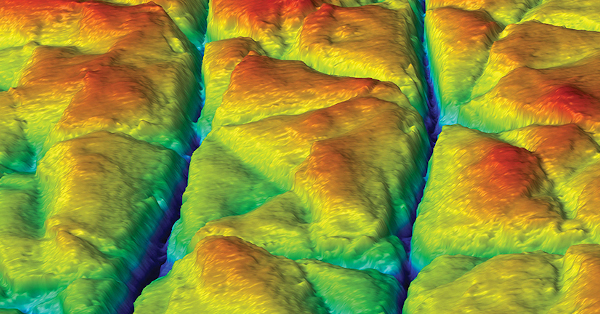

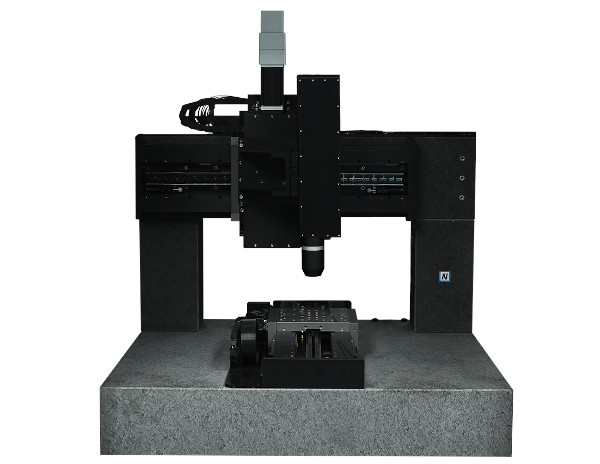

We supply 3D non-contact profilometers from Nanovea of Irvine California. Nanovea combine advanced Chromatic Confocal technology with powerful software to gather and analyse detailed height data about a wide variety of sample types. With a single profilometry scan it is possible to obtain measurements such as 3D waviness, roughness, step height, film thickness through to advanced fractal analysis and particle characterization.

You can find out more on the Nanovea website here.

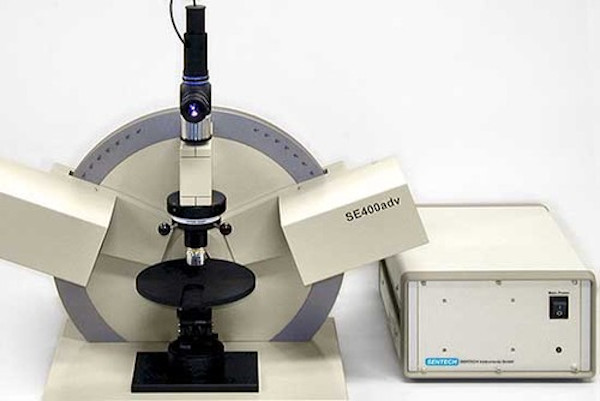

A comprehensive solution for laboratories using several types of microscope and profilometer

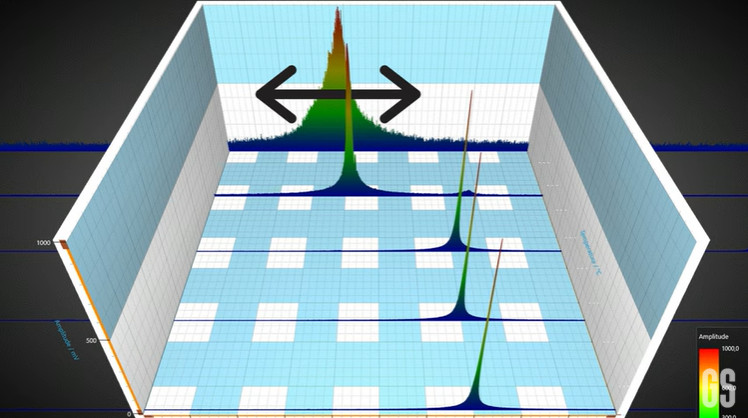

Benchmark technology for 2D and 3D surface texture analysis and metrology, seamlessly integrates with profilometers and other surface measuring equipment

Measure surface roughness, form, profile, finish plus more

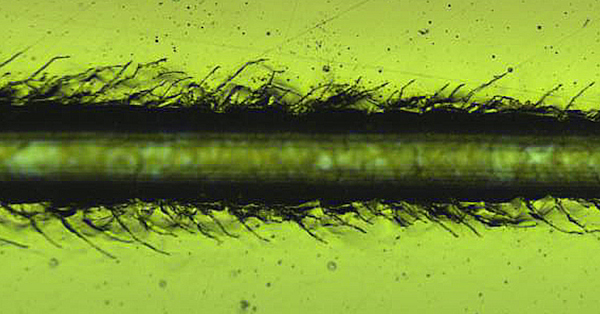

Profilometer sensors and software for in-line integration

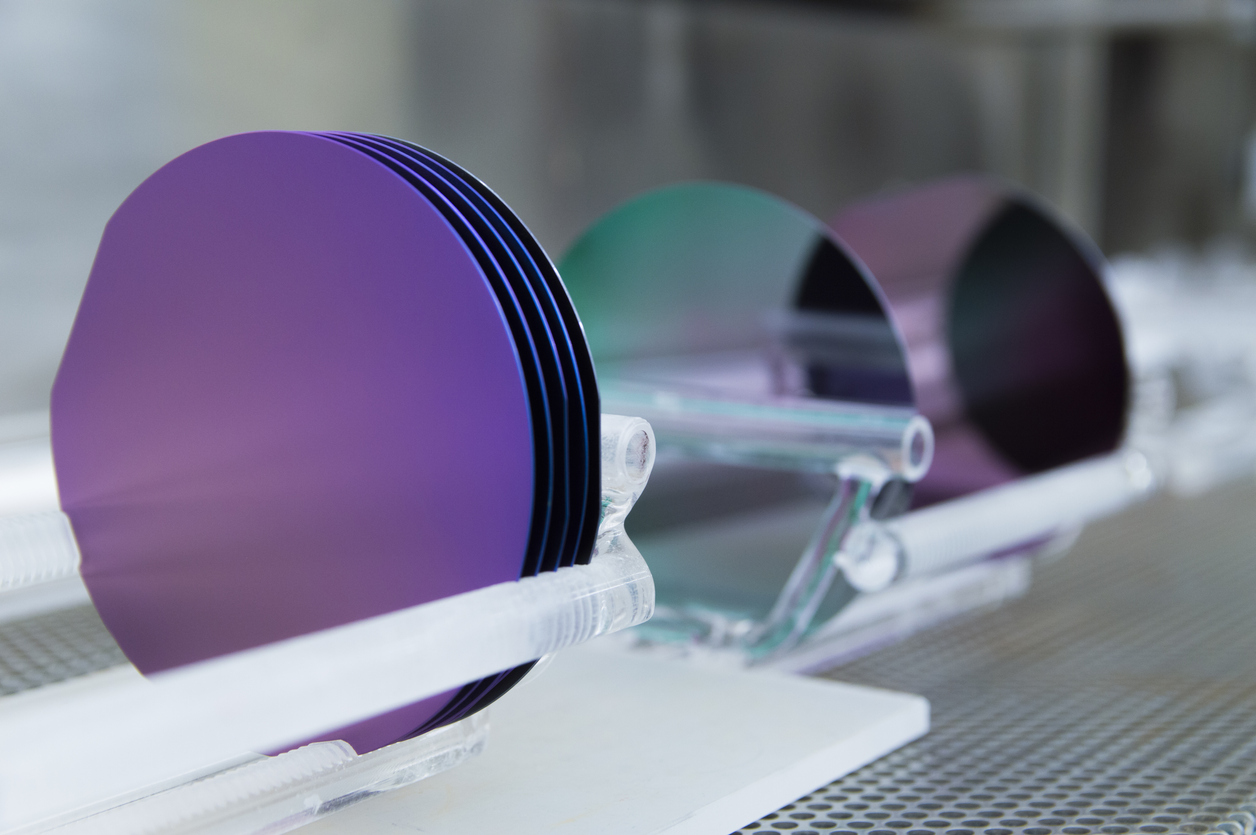

Large area high speed flatness measurements on a non-contact 3D surface profilometer

Contact us

We’d love to hear from you

We’re here and ready to provide information and answers to your questions

Policy Information

©Mi-Net 2023. All Rights Reserved.

Website by Fifteen.co.uk