Testing & Analysis

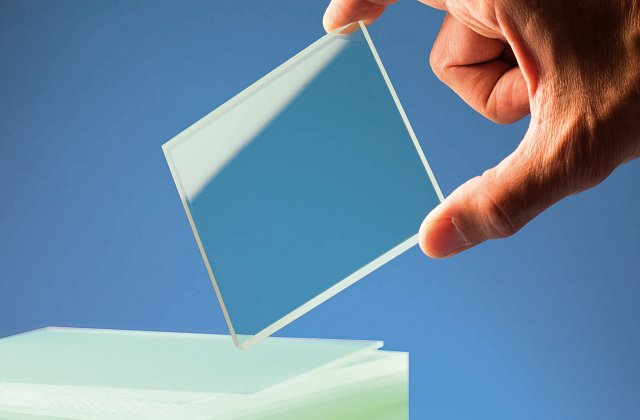

Instrumentation for materials testing and analysis in research and manufacturing settings

Our testing and analysis instruments are used across a broad range of applications and industries. They are used in both low and high throughput environments for research through to quality control and manufacturing.

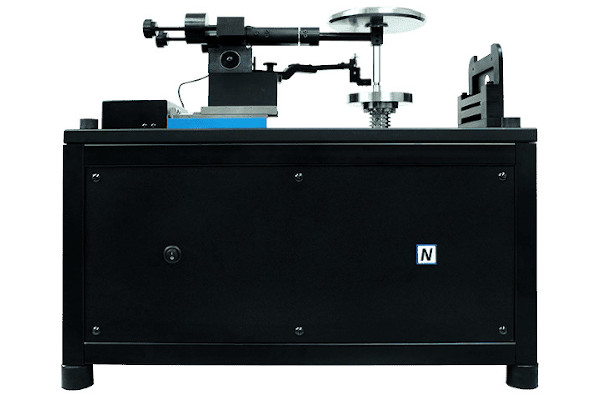

Scratch, indentation and wear testing all on one tool at nano and micro load ranges

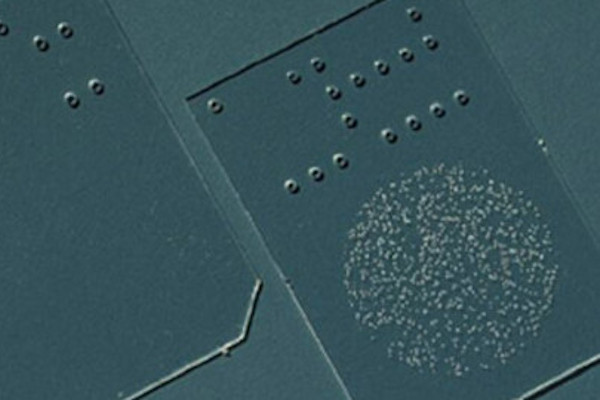

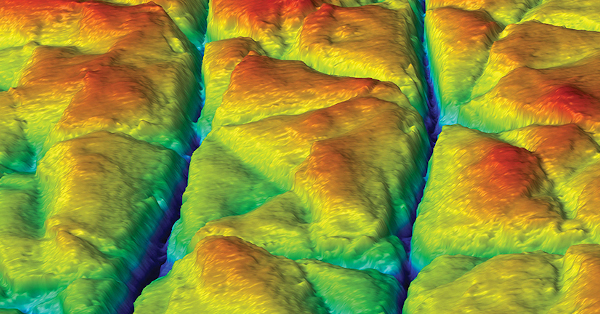

3D non-contact profilometers for collecting and analyzing sample height data

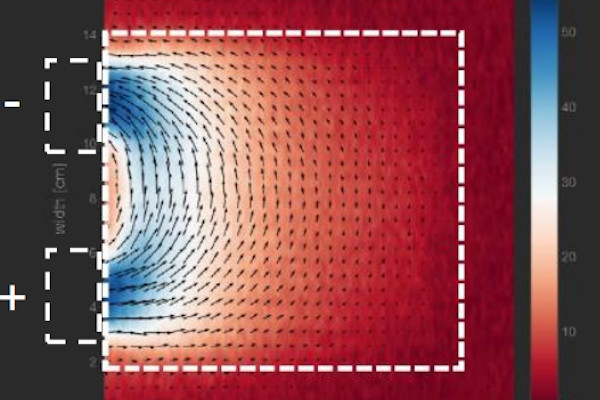

Non-contact technology measuring real time strength and direction of electrical currents

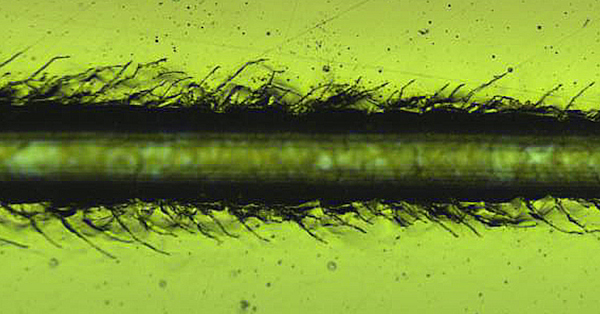

Reproducing the wear interaction between a surface and the human finger

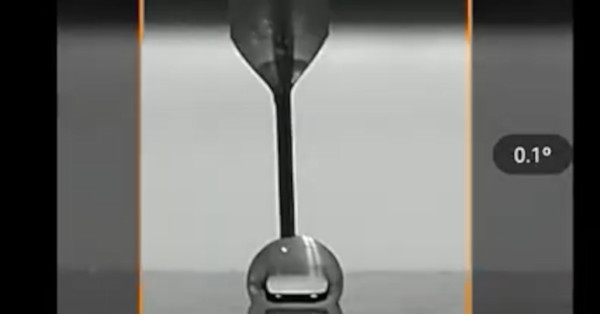

Accurate information about surface tension, contact angle, surface energy and sliding angle

Advanced 3D optical measurement solutions for quality assurance in production

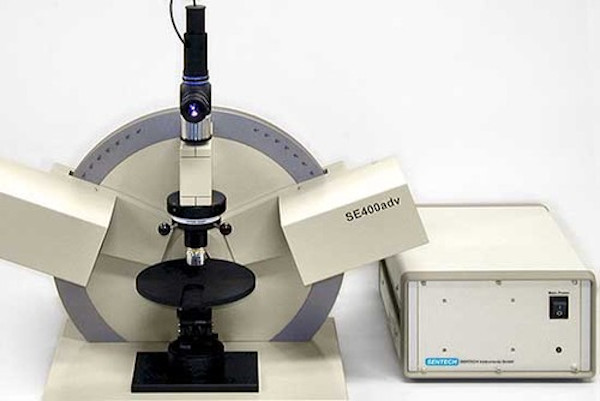

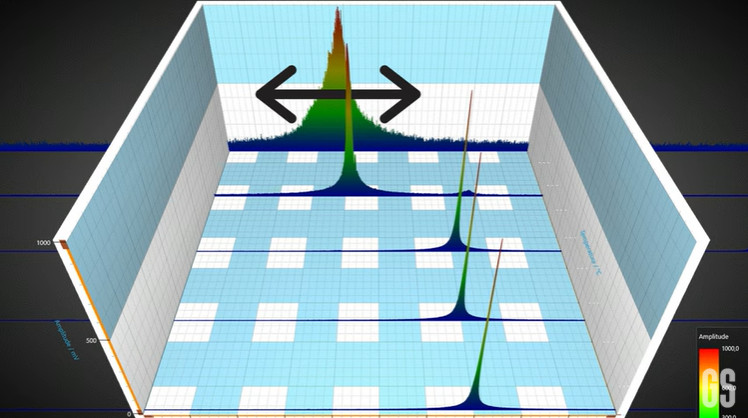

A non-destructive technique used to determine internal mechanical properties of bulk materials.

Featured products

Explore featured products from across our product range

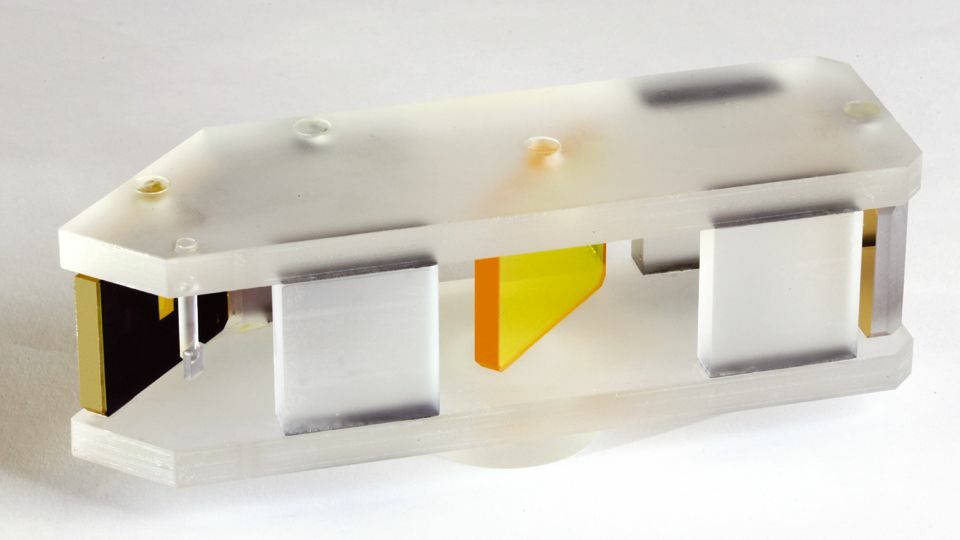

Scratch, indentation and wear across Nano or Micro load ranges on a compact benchtop platform

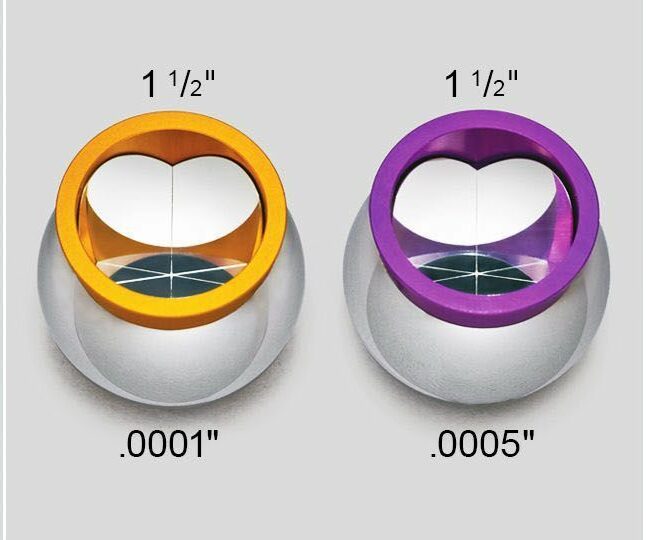

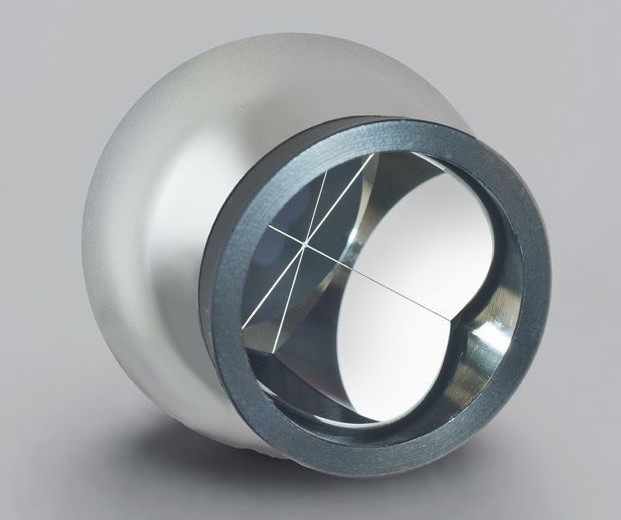

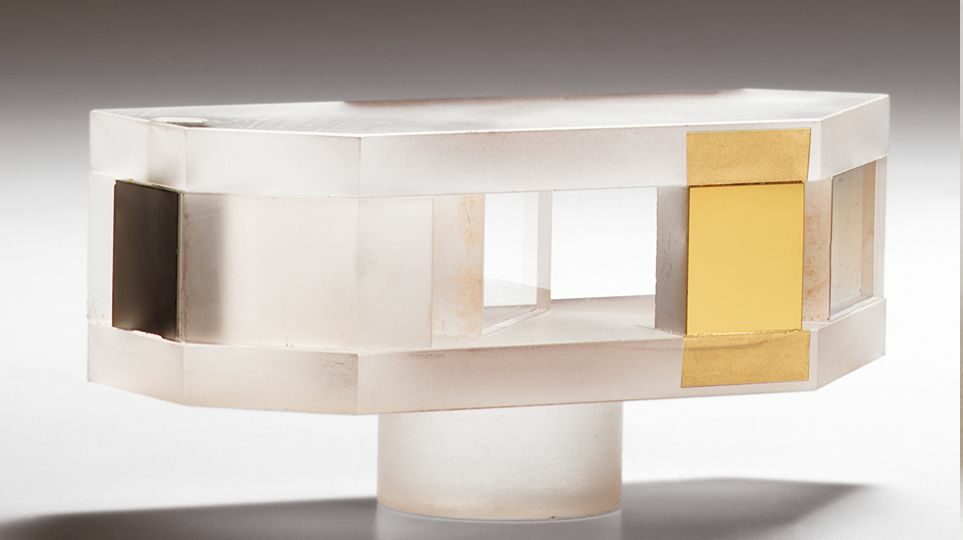

Superb optical stability and unsurpassed shock and vibration resistance which lasts indefinitely

Industries

Our products are used in a range of industries worldwide

Research and quality control in the pharmaceuticals and cosmetics industry...Find out more

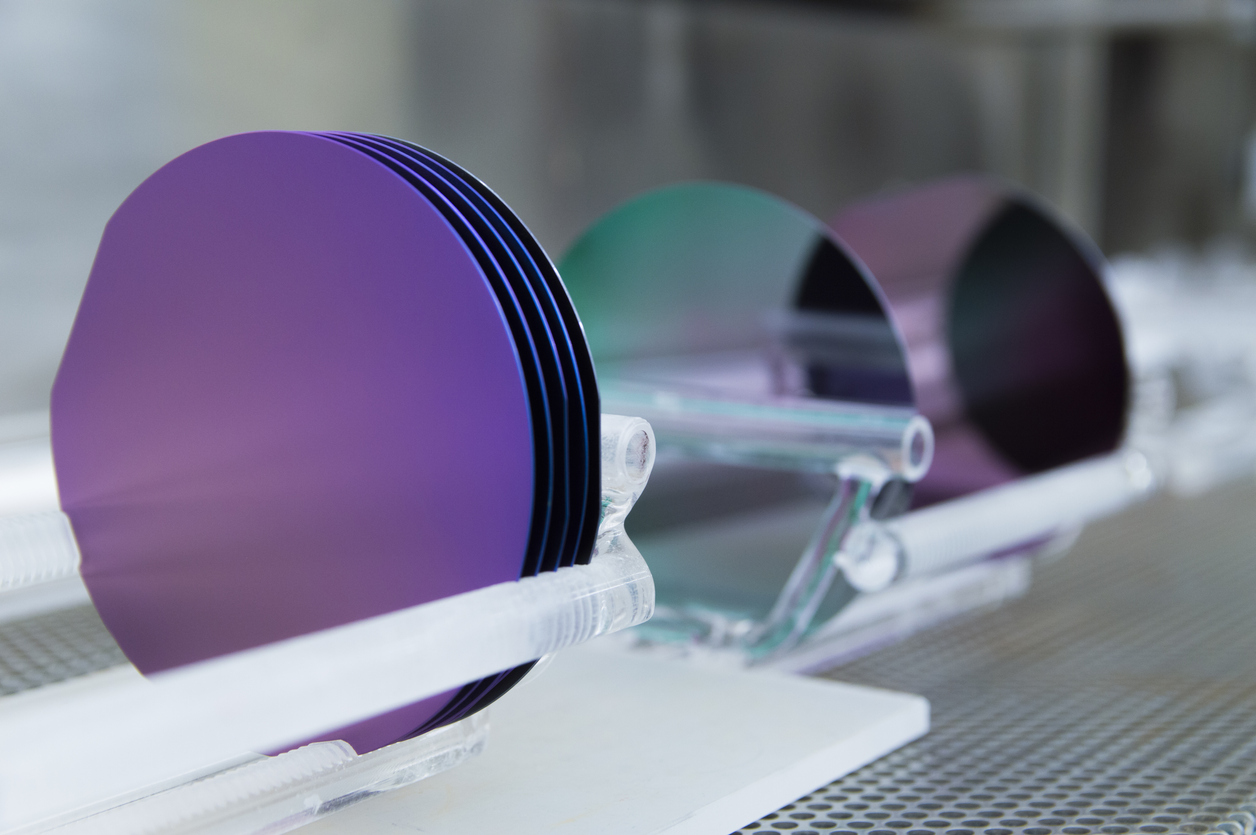

The design and fabrication of semiconductor devices within the wider...Find out more

Contact us

We’d love to hear from you

We’re here and ready to provide information and answers to your questions

Policy Information

©Mi-Net 2023. All Rights Reserved.

Website by Fifteen.co.uk