Textiles

The design and production of cloth goods using natural or synthetic raw materials

Textile materials are known as cloth goods produced using natural or synthetic raw materials. Some example textiles are fabrics, leathers and paper and all differ in appearance, durability and feel depending on the manufacturing process and material composition.

Analytical instruments can be used to characterize textiles for internal R&D and for external promotion.

Internally understanding more about the properties of textiles allows manufacturers to improve the manufacturing process and to do so methodically and with less risk. Textiles can be tested and prototyped well before any changes are made to the end manufacturing process and manufacturers can have confidence that investing in these changes will yield positive results.

Externally the data gathered from textile testing can be used to prove performance of textile products and to justify cost. More than ever customers want data to prove performance of technical products or robustness of textiles.

Products for Textile analysis

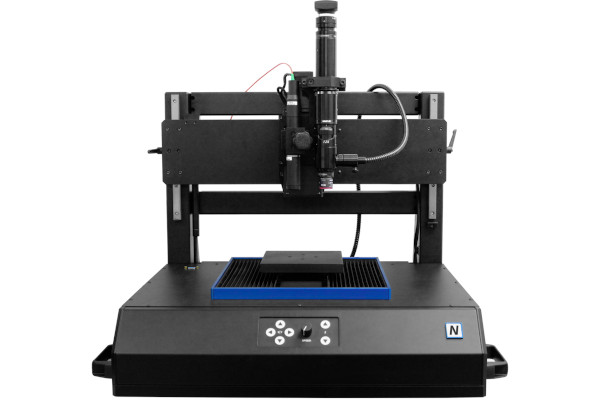

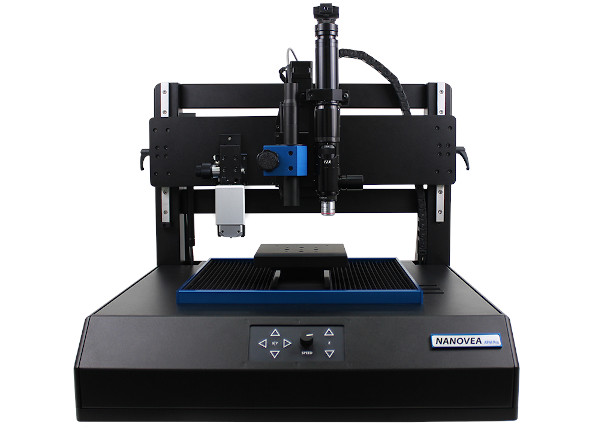

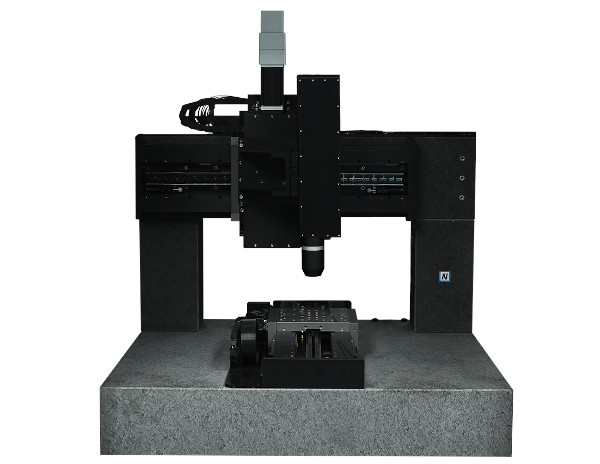

We supply products from Nanovea of Irvine California that have already been used extensively for textile research. Their range of profilometers are used to evaluate properties such as roughness, texture, consistency and patterning whilst their range of mechanical testers and tribometers are used to evaluate physical properties such as resistance to abrasion and scratches.

Complementing the Nanovea range we supply a hand abrasion tester from Tribotron of Switzerland. The Tribotouch tester simulates the human touch and can perform real life testing of finished products or lab samples in respect to hand abrasion.

Application Examples

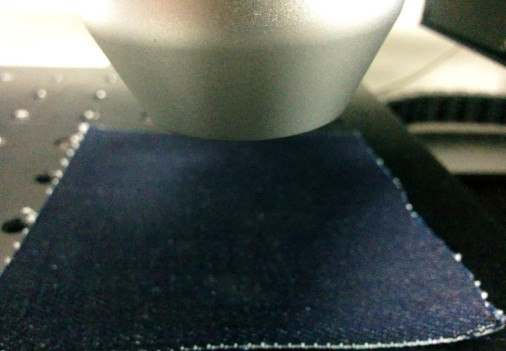

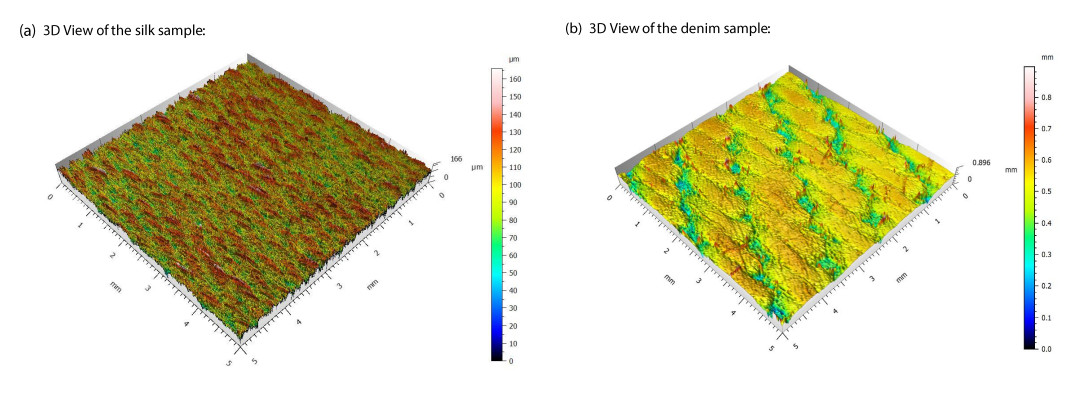

3D non-contact profilometry is used to analyze and compare surface textures of different textiles. In this application note Nanovea have compared the texture of silk and denim samples. In the application note height parameters are presented next to a histogram plot of particle sizes.

Non contact profilometry is ideal for testing textiles such as silk which may be damaged by contact testing methods. Having height data on the micrometer level allows the user to have a greater understanding about why their textiles feel or behave in a certain way and to make appropriate amendments to processing to alter these behaviours.

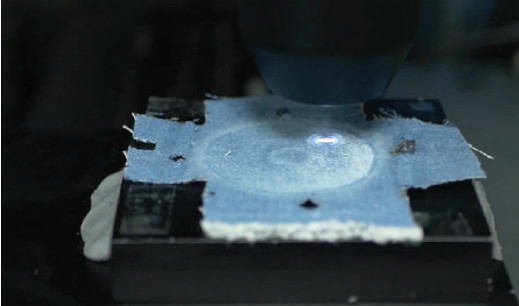

Pin on disc tribology is used to analyze the abrasion wear process of two denim samples, raw and washed. Nanovea have used their T50 tribometer to simulate wear in a controlled and monitored manner. The HS2000 high speed profilometer is then used to collect height data to further analyze the results of the wear test.

In the textile industry these tests are extremely useful in understanding how different textiles will wear over time and in understanding the durability of a textile. In the clothing industry it is important to understand how the look and colour of a textile will change as it wears.

Popular products used within this industry

Other industries

Research and quality control in the pharmaceuticals and cosmetics industry...

The design and fabrication of semiconductor devices within the wider...

Contact us

We’d love to hear from you

We’re here and ready to provide information and answers to your questions

Policy Information

©Mi-Net 2023. All Rights Reserved.

Website by Fifteen.co.uk