Display Solutions

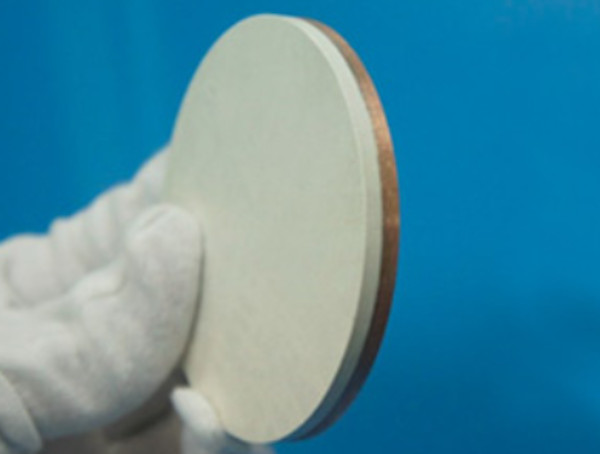

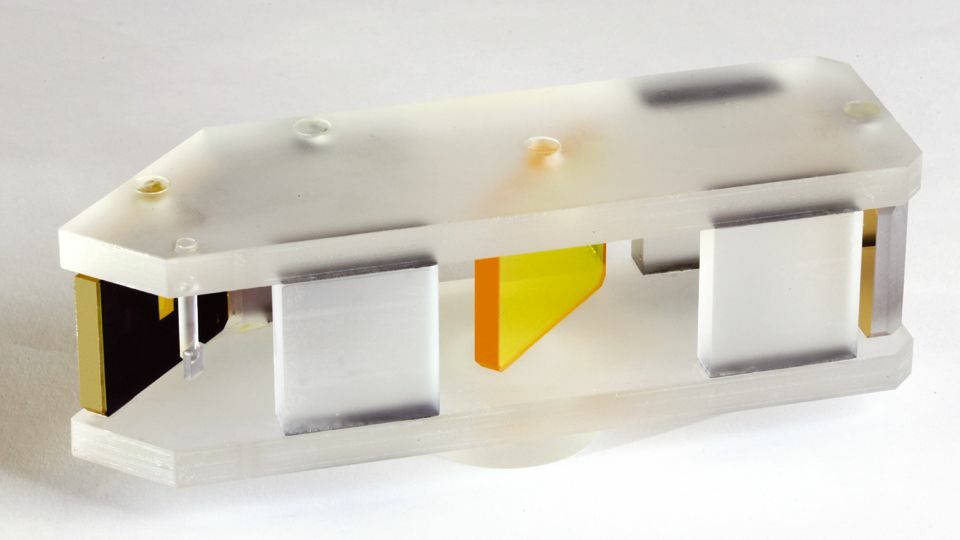

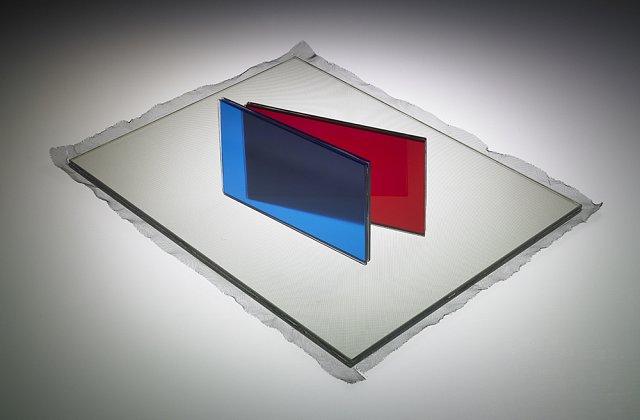

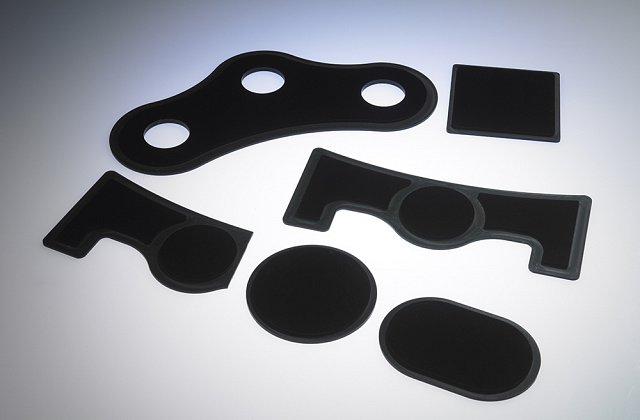

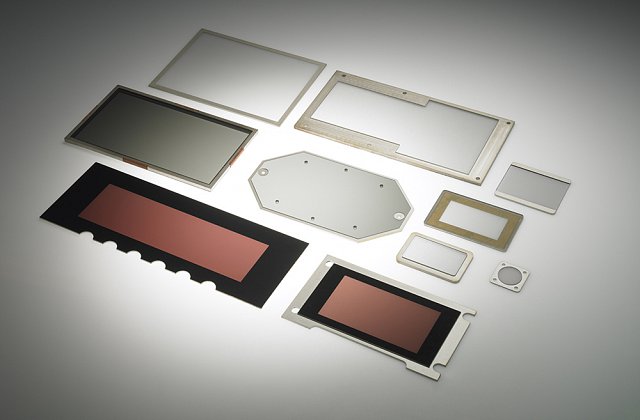

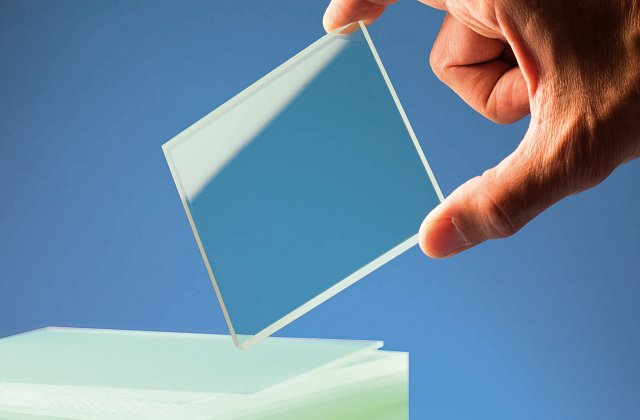

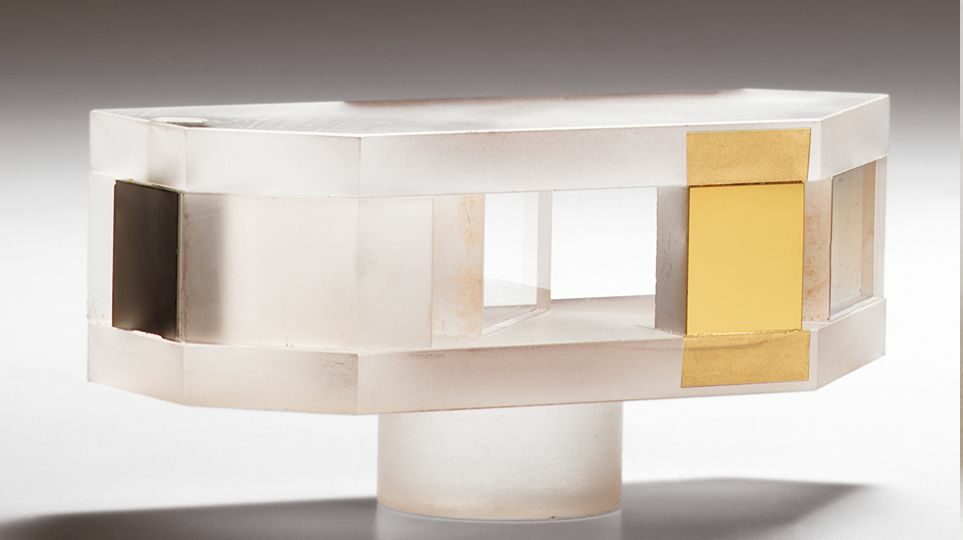

Materials for use in display applications

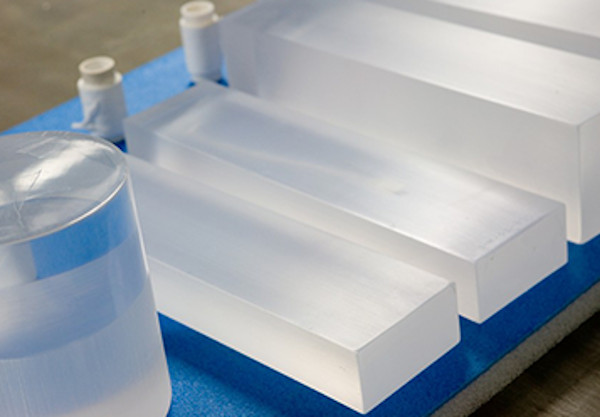

We supply a variety of films, plastics and glasses for use in display applications.

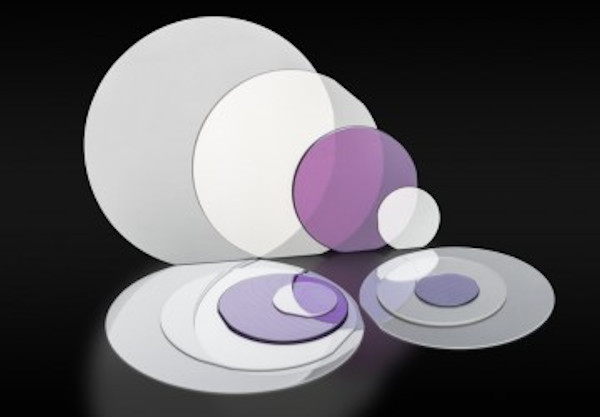

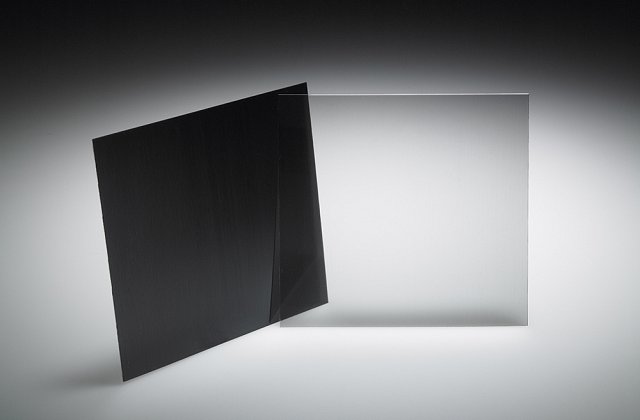

Transmit infrared radiation whilst being opaque to visible light

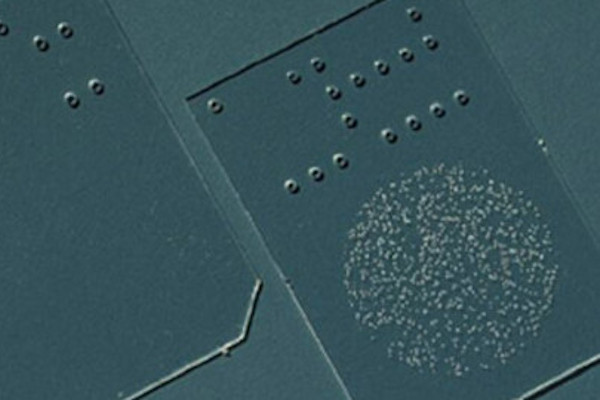

Combining electromagnetic shielding with excellent contrast enhancement

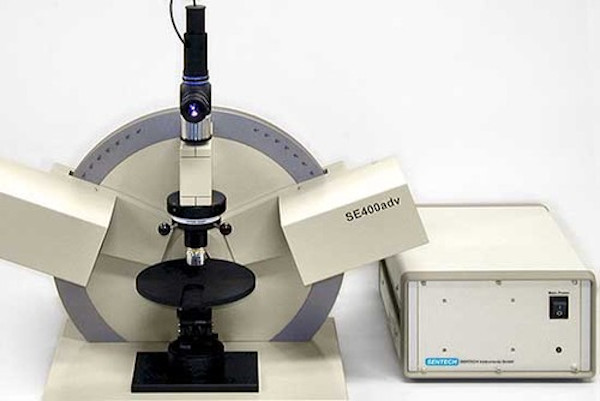

Plastic optical filter with broadband AR coating on both sides

Featured products

Explore featured products from across our product range

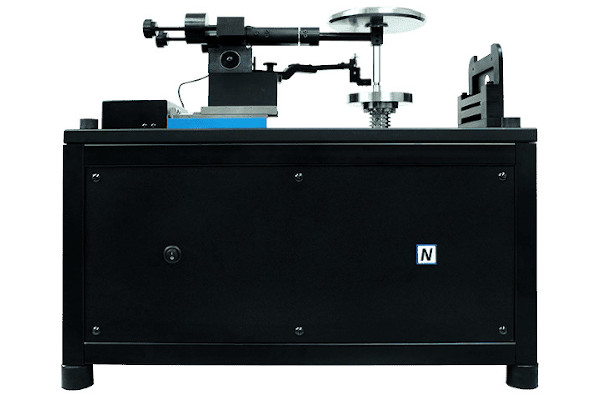

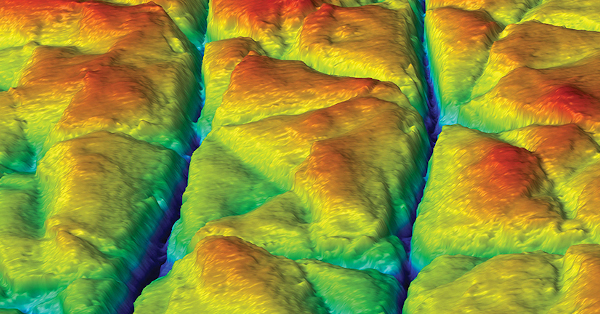

Scratch, indentation and wear across Nano or Micro load ranges on a compact benchtop platform

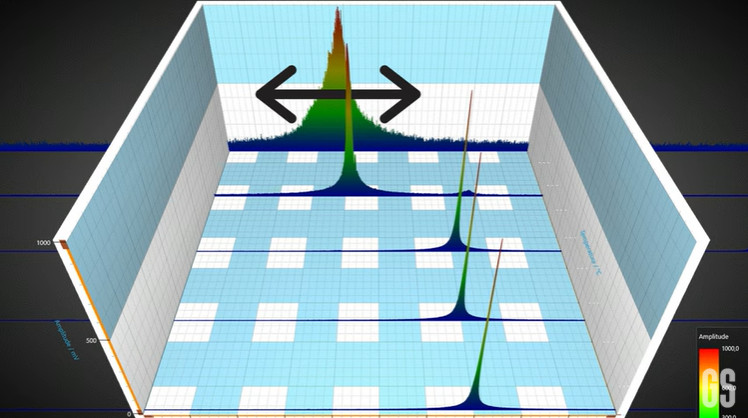

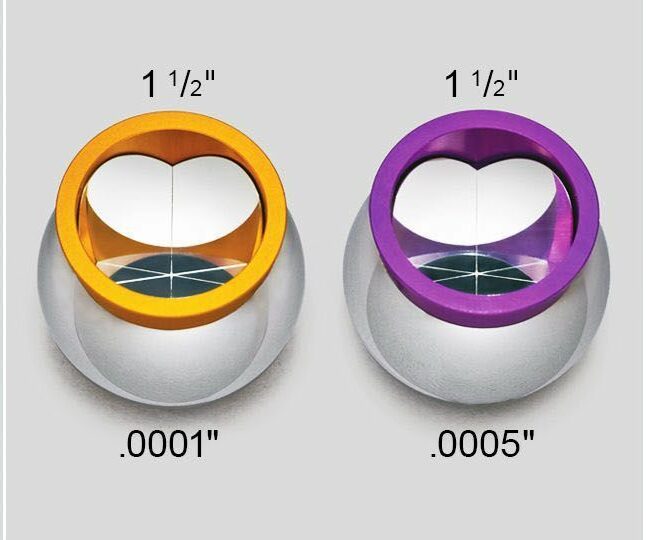

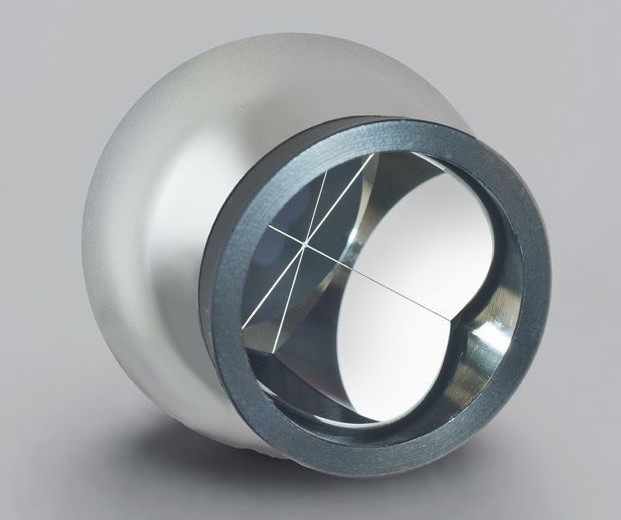

Superb optical stability and unsurpassed shock and vibration resistance which lasts indefinitely

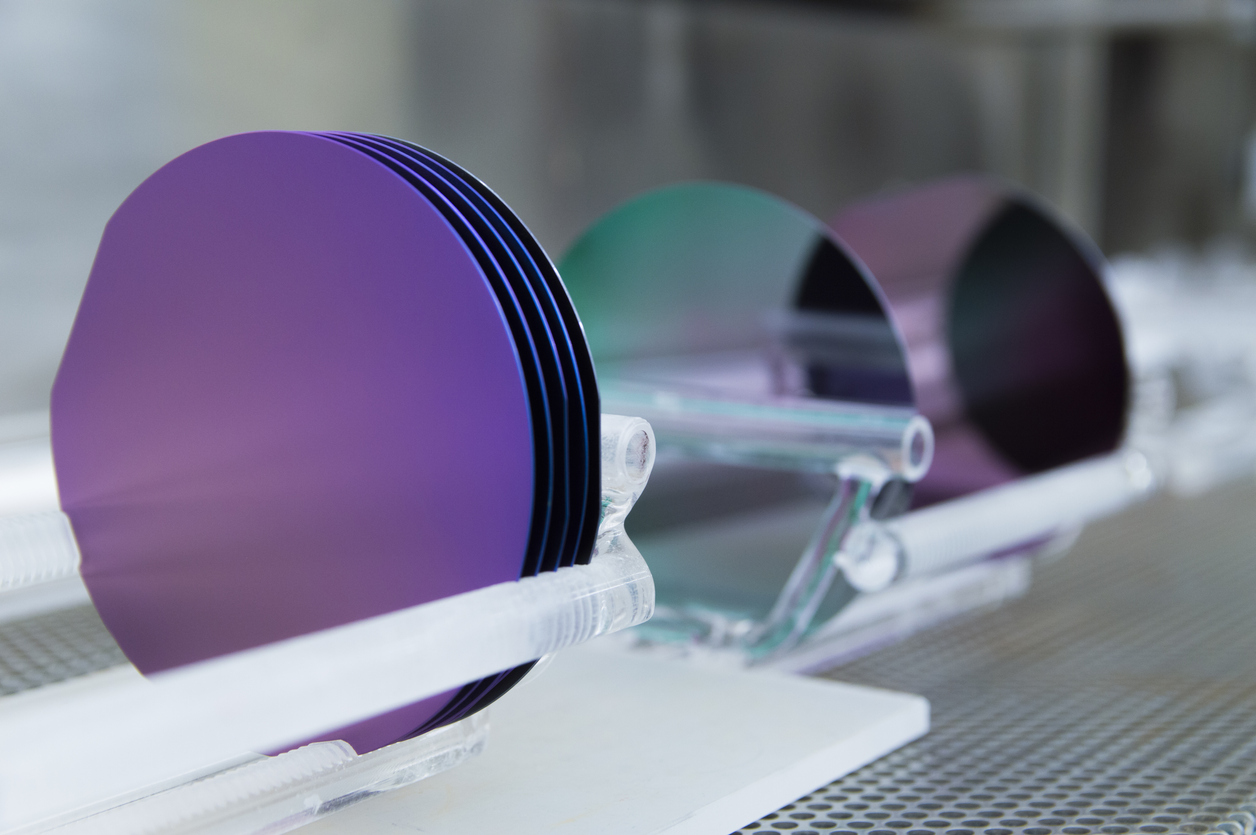

Industries

Our products are used in a range of industries worldwide

The design and fabrication of semiconductor devices within the wider...

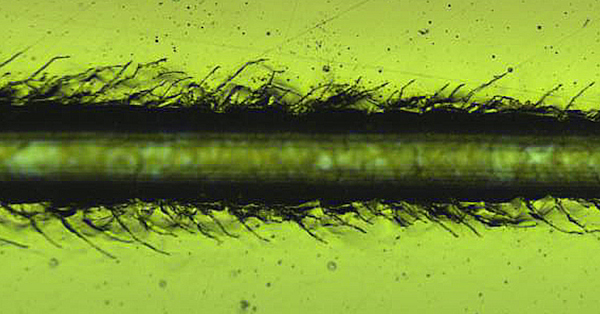

Research and quality control in the pharmaceuticals and cosmetics industry...

Contact us

We’d love to hear from you

We’re here and ready to provide information and answers to your questions

Policy Information

©Mi-Net 2023. All Rights Reserved.

Website by Fifteen.co.uk